ʻO nā paipu a me nā paipu ʻole Titanium

ʻO Gr1, Gr 2, Gr 3 nā mea hana a pau o ka titanium maʻemaʻe. Loaʻa iā lākou nā waiwai mechanical kiʻekiʻe, hana stamping maikaʻi loa, a hiki ke welded i nā ʻano like ʻole. Hiki i ka ikaika o ka hui welded ke hiki i 90% o ka ikaika o ka metala kumu, a maikaʻi ka hana ʻoki. He kiʻekiʻe ka pale ʻana o ka pahu Titanium i ka chloride, sulfide a me ka amonia. ʻOi aku ka kiʻekiʻe o ka pale ʻana o ka titanium i loko o ka wai kai ma mua o nā alumini alumini, ke kila kila, a me nā nickel-based alloys. Paʻa pū ka Titanium i ka hopena o ka wai.

Hoʻohana nui ʻia ka Titanium alloy no ka hana ʻana i nā ʻāpana compressor mīkini mokulele, a ukali ʻia e nā ʻāpana kūkulu o nā rockets, missiles a me nā mokulele kiʻekiʻe. Ma ka waena waena o 1960s, ua hoʻohana ʻia ka titanium a me kāna mau mea hoʻohui i ka ʻoihana maʻamau e hana i nā electrodes i ka ʻoihana electrolysis, condensers i nā mana mana, nā mea hoʻomehana no ka hoʻomaʻemaʻe ʻaila a me ka desalination o ke kai, a me nā mea hoʻokele pollution kaiapuni. Ua lilo ʻo Titanium a me kāna mau mea hoʻoheheʻe ʻia i ʻano mea hoʻolālā kū i ka corrosion. Eia kekahi, hoʻohana ʻia ia i ka hana ʻana i nā mea mālama hydrogen a hoʻohālikelike i nā alloys hoʻomanaʻo.

Ke hoʻohālikelike ʻia me nā mea metala ʻē aʻe, ʻo ka titanium alloy nā mea maikaʻi aʻe:

- ʻO ka ikaika kikoʻī kiʻekiʻe (ikaika tensile / density), hiki i ka ikaika tensile ke piʻi i 100 ~ 140kgf / mm2, a ʻo 60% wale nō ka nui o ke kila.

- He ikaika maikaʻi ka mahana wela, ʻoi aku ka nui o ka mahana o ka hoʻohana ʻana ma mua o ka alumini alumini, hiki ke mālama i ka ikaika i koi ʻia ma ka mahana wela, a hiki ke hana no ka manawa lōʻihi ma kahi mahana o 450 ~ 500 ℃.

- Kūleʻa maikaʻi i ka corrosion. Hoʻokumu koke ʻia kahi kiʻi ʻoniʻoni ʻoniʻoni a me ka oxide ma ka ʻili o ka titanium i ka lewa, nona ka hiki ke pale aku i ka corrosion e nā ʻano media. ʻO ka maʻamau, ʻoi aku ka maikaʻi o ka titanium i ke kūpaʻa corrosion i ka oxidizing a me ka neutral media, a ʻoi aku ka maikaʻi o ke kūpaʻa corrosion i loko o ka wai kai, wai chlorine a me nā hāʻina chloride. Akā i ka hōʻemi ʻana i ka media, e like me ka hydrochloric acid a me nā hopena ʻē aʻe, maikaʻi ʻole ka pale ʻana o ka titanium.

- Hiki i nā huila Titanium me ka maikaʻi haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa haʻahaʻa, e like me Gr7, hiki ke mālama i kahi pae o ka plasticity ma -253 ℃.

- He haʻahaʻa ka modulus o ka elasticity, liʻiliʻi ka conductivity thermal, a he non-ferromagnetic.

He loea ʻo BMT i ka hoʻokuʻu ʻana i nā paipu titanium seamless a me nā paipu, a nona ka hana makahiki o 5,000 tons. ʻO nā paipu a me nā paipu ʻole BMT e hōʻike ana i ka ikaika kikoʻī kiʻekiʻe, ka pale ʻana i ka corrosion, ka waiwai cryogenic maikaʻi, ka modulus elasticity haʻahaʻa, ka conductivity thermal haʻahaʻa a ʻaʻohe ferromagnetism.

Ke kūʻai aku nei ka nui o BMT o ka paipu titanium maʻemaʻe a puni ka honua. Hoʻokō ʻia ka mākaʻikaʻi Righd ma ke ʻano o ka maikaʻi, me ka nānā ʻana i nā ʻāpana chemial, ka hoʻāʻo ʻana i ke ea, ka hoʻāʻo nondestructive, ka hoʻāʻo eddy a me ka hoʻāʻo ultrasonic. Loaʻa iā mākou ka hoʻāʻo mechanical, uhi i ka hoʻāʻo tensile, hoʻāʻo flaring, hoʻāʻo hoʻopalapala, hoʻāʻo ferroxyl, RT, X-Ray test, etc.

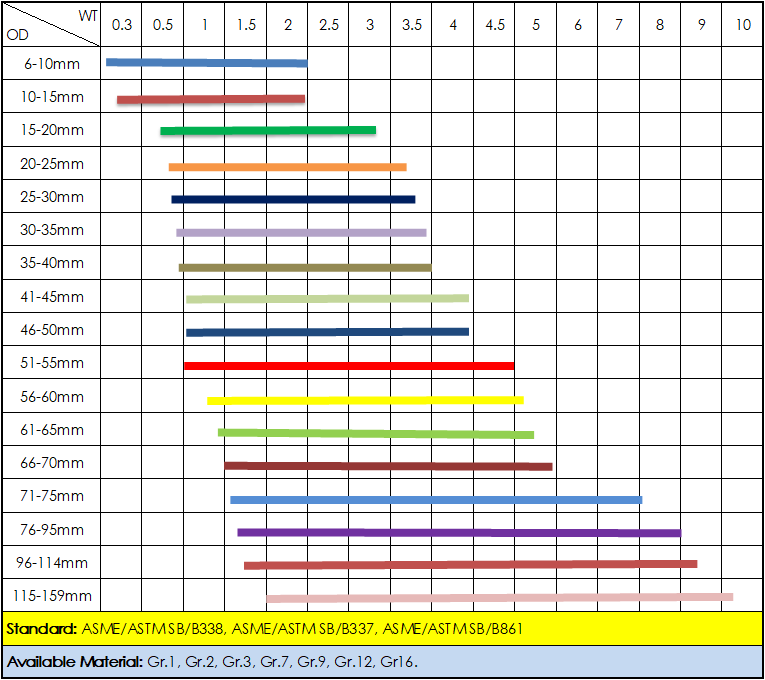

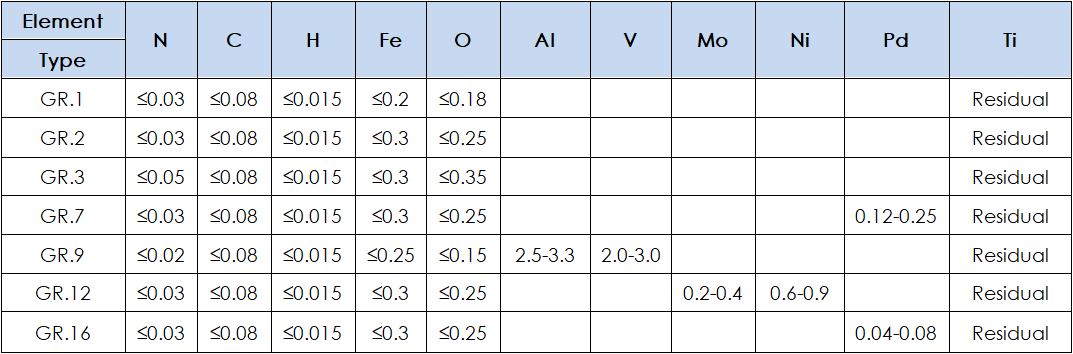

ʻO ka nui o ka nui o nā paipu a me nā paipu Titanium:

Loaʻa i nā mea hana kemika:

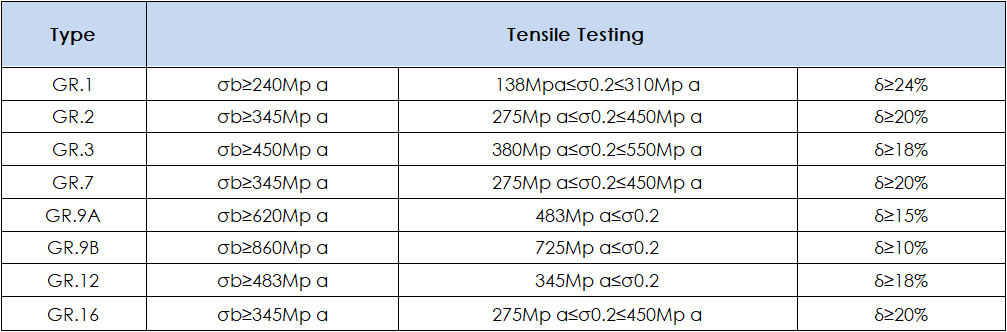

Mea Loaʻa Mechanical Property:

Hoʻāʻo nānā:

- ʻIkepili Kimia

- Hoao Mechanical Property

- ʻO ka hoʻāʻo ʻana

- Hoʻāʻo ʻana i ke ahi

- Ho'āʻo palahalaha

- Ho'āʻo Kulou

- Ho'āʻo Hydro-Static

- Ho'āʻo Pneumatic (Ho'āʻo i ke ea ma lalo o ka wai)

- NDT hoao

- Eddy-I kēia manawa

- Ho'āʻo Ultrasonic

- Hoao LDP

- Hoao Ferroxyl

Huahana (Max a me Min nui o ke kauoha):palena ʻole, e like me ke kauoha.

Ka manawa o waena o ka hoʻomaka a i ka wā pau:ʻO ka manawa alakaʻi maʻamau he 30 mau lā. Eia naʻe, pili ia i ka nui o ke kauoha accrdingly.

Kaʻahele:ʻO ke ala maʻamau o ka lawe ʻana ma ke Kai, ma ka Air, ma Express, ma Train, e koho ʻia e nā mea kūʻai.

Hoʻopili:

- E pale ʻia nā ʻaoʻao o ka paipu me ka plastic a i ʻole ka pahu pahu.

- Hoʻopili ʻia nā mea pono a pau e pale i nā welau a me ke alo.

- Hoʻopili ʻia nā waiwai ʻē aʻe a pau e nā pad foam a me nā pahu plastik pili a me nā pahu plywood.

- Pono pono kēlā me kēia lāʻau i hoʻohana ʻia no ka hoʻopili ʻana i mea e pale ai i ka hoʻohaumia ʻana ma o ka hoʻopili ʻana me nā lako hana.