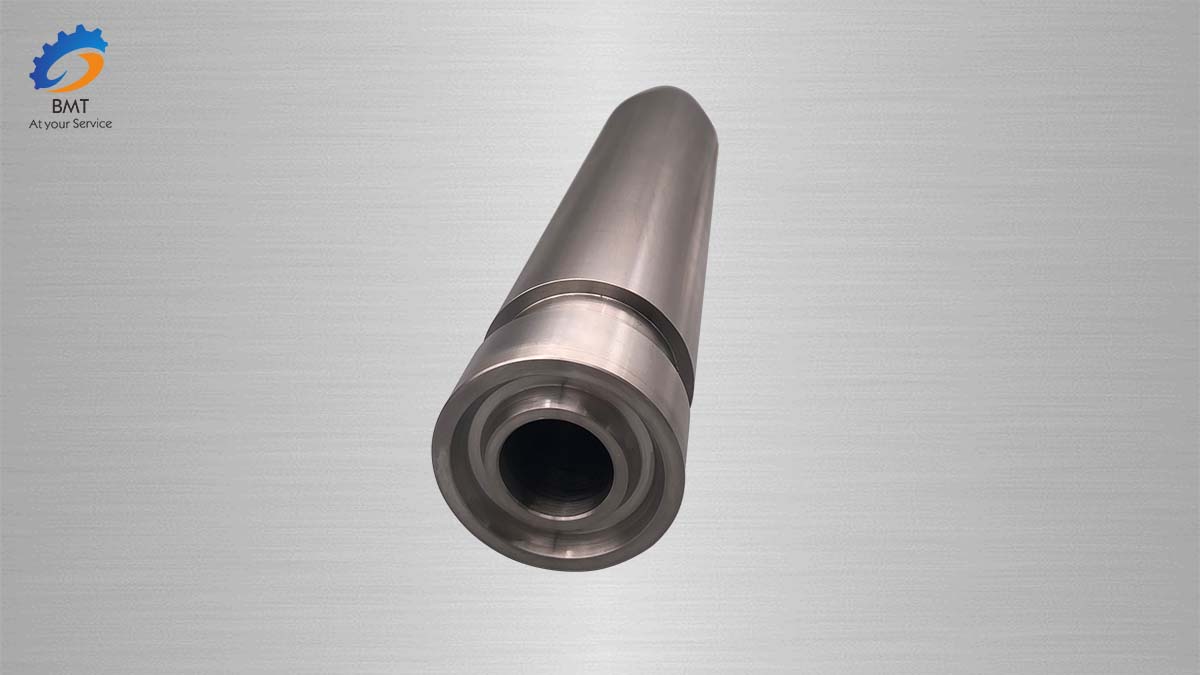

Titanium Alloy CNC Mīkini

ʻOi aku ka like o ka mīkini paʻi ʻana o nā titanium alloys me ka mīkini kila ma mua o nā metala non-ferrous a me nā alloys. Nui nā ʻāpana kaʻina o nā alloys titanium i ka forging, leo stamping a me ka sheet stamping kokoke i nā mea i ka hana kila. Akā aia kekahi mau hiʻohiʻona koʻikoʻi e pono e hoʻolohe i ka wā e paʻi ai i ka hana Chin a me Chin alloys.

ʻOiai ke manaʻoʻiʻo ʻia ʻo nā lattices hexagonal i loko o ka titanium a me ka titanium alloys ʻoi aku ka liʻiliʻi o ka ductile i ka wā deformed, nā ʻano hana paʻi like ʻole i hoʻohana ʻia no nā metala kūkulu ʻē aʻe e kūpono no nā alloys titanium. ʻO ka lakio o ka helu hua i ka palena ikaika ʻo ia kekahi o nā hōʻailona hiʻohiʻona inā hiki i ka metala ke kū i ka deformation plastic. ʻO ka nui o kēia ratio, ʻoi aku ka maikaʻi o ka plasticity o ka metala. No ka titanium maʻemaʻe ʻoihana i loko o ka moku maloʻo, ʻo ka ratio he 0.72-0.87, hoʻohālikelike ʻia me 0.6-0.65 no ke kila kalapona a me 0.4-0.5 no ke kila kila.

E hoʻokō i ka hoʻopaʻa ʻana i ka leo, ka hoʻoheheʻe manuahi a me nā hana ʻē aʻe e pili ana i ka hana ʻana i ka ʻāpana keʻa nui a me nā blanks nui nui ma ke kūlana wela (ma luna o ka =yS ka wela hoʻololi). ʻO ka pae wela o ka hoʻopaʻa ʻana a me ka hoʻoheheʻe ʻana ma waena o 850-1150 ° C. Alloys BT; M0, BT1-0, OT4 ~ 0 a me OT4-1 loaʻa ka deformation plastik maikaʻi i ka mokuʻāina maloʻo. No laila, ʻo nā ʻāpana i hana ʻia i kēia mau ʻāpana i hana ʻia me nā blanks annealed intermediate me ka ʻole o ka hoʻomehana ʻana a me ke kahakaha ʻana. Ke hoʻoheheʻe ʻia ka titanium alloy i ka plastically deformed, me ka nānā ʻole i kona ʻano kemika a me nā waiwai mechanical, e hoʻomaikaʻi nui ʻia ka ikaika, a e hoʻemi ʻia ka plasticity. No kēia kumu, pono e hana ʻia ka hana annealing ma waena o nā kaʻina hana.

ʻO ke kāʻei o ka insert groove i ka mīkini ʻana o nā titanium alloys ka lole kūloko o ke kua a me ke alo i ke kuhikuhi o ka hohonu o ka ʻoki, i hana pinepine ʻia e ka papa paʻakikī i waiho ʻia e ka hana mua. ʻO ka hopena kemika a me ka hoʻopuehu ʻana o ka mea hana a me ka mea hana ma kahi mahana hana ʻoi aku ma mua o 800 °C kekahi o nā kumu no ka hoʻokumu ʻana i ke kapa komo. No ka mea, i ka wā o ka mīkini hana, hōʻuluʻulu ʻia nā molekala titanium o ka mea hana i mua o ka maka a "welded" i ka ʻaoʻao o ka lau ma lalo o ke kiʻekiʻe kiʻekiʻe a me ke kiʻekiʻe kiʻekiʻe, e hana ana i kahi kihi i kūkulu ʻia. Ke ʻili ka lihi i kūkulu ʻia i ka ʻoki ʻoki, lawe ʻia ka uhi carbide o ka mea hoʻokomo.

Ma muli o ke kūpaʻa wela o ka titanium, he mea koʻikoʻi ka hoʻomaha ʻana i ke kaʻina hana. ʻO ke kumu o ka hoʻomaha ʻana ʻo ia ka mālama ʻana i ka ʻoki ʻoki a me ka ʻili o ka mea hana mai ka wela. E hoʻohana i ka mea hoʻoluʻu hope no ka hoʻokuʻu ʻana i nā puʻupuʻu i ka wā e hana ana i ka wili poʻohiwi a me nā ʻeke wili maka, ʻeke a i ʻole nā awāwa piha. I ka wā e ʻoki ai i ka metala titanium, ua maʻalahi nā ʻōpala e pili i ka ʻoki ʻoki, e hoʻoneʻe ai i ka pōʻai ʻoki wili aʻe e ʻoki hou i nā ʻāpana, e ʻoki pinepine ai i ka laina lihi.

Loaʻa i kēlā me kēia lua hoʻokomo kona puka hoʻomāmā ponoʻī / injection e hoʻoponopono i kēia pilikia a hoʻomaikaʻi i ka hana lihi mau. ʻO kekahi hoʻonā maʻemaʻe ʻo ia nā lua hoʻoluʻu wili. He nui nā mea hoʻokomo i nā mea ʻoki wili lihi lōʻihi. ʻO ka noi ʻana i ka mea hoʻoluʻu i kēlā me kēia puka e pono ai ka mana kiʻekiʻe a me ke kaomi. Ma ka ʻaoʻao ʻē aʻe, hiki iā ia ke hoʻopili i nā puka pono ʻole e like me ka mea e pono ai, a laila e hoʻonui i ka kahe i nā lua e pono ai.

E hoʻouna i kāu leka iā mākou:

-

Aluminum CNC Mīkini Māhele

-

Hana Metala Aluminum

-

ʻAxis High Precision CNC Machining Parts

-

Nā ʻāpana mīkini CNC no Italia

-

ʻO nā ʻāpana alumini CNC Machining

-

Mīkini ʻāpana Kaʻa

-

ʻO nā mea hoʻoheheʻe Titanium Alloy

-

ʻO nā mea hoʻopili Titanium a me Titanium Alloy

-

ʻO nā mea hoʻopili Titanium a me Titanium Alloy Forgings

-

ʻO nā uwea huila Titanium a me Titanium

-

Nā Bara Titanium

-

ʻO nā paipu hili ʻole Titanium

-

ʻO nā paipu welded Titanium