5 mau ala e hoʻomaikaʻi ai i nā ʻāpana metala

ʻO ka hana ʻana i nā ʻāpana metala he mea maʻalahi o nā kaʻina hana i hoʻohana ʻia e hana i nā ʻāpana mai nā ʻāpana palahalaha. Hele mai ka metala laula i nā ʻano mea a me nā mānoanoa, a hiki ke hoʻohana ʻia e hana i nā ʻāpana e like me nā mea hana, nā pā, nā pale, nā panela a me nā chassis, etc.

Hoʻohālikelike ʻia me ka CNC machining, ua kuhikuhi ʻia ka hana ʻana o ka metala e nā kikoʻī hoʻolālā koʻikoʻi. No kekahi poʻe hana hou no ka hana ʻana i ka metala, paʻakikī paha ia. Pono e kūlou a ʻokiʻoki ʻia ka lau metala ma nā ʻano like ʻole, a kūpono wale ia no kekahi mau ʻāpana a me nā huahana.

ʻO ka mea ʻoiaʻiʻo, he mea nui e aʻo i kekahi mau kumu kumu o ka hana ʻana i ka metala ma mua o ka hana ʻana. Me ka hoʻohana ʻana i ka hana metala, hiki i nā ʻenehana ke hana i nā ʻāpana kūʻai haʻahaʻa mai nā mea like ʻole. Hiki ke hoʻohana ʻia kēia mau ʻāpana ma waena o nā ʻoihana like ʻole, mai ka aerospace a i ka mea hana home.

ʻO ka mānoanoa metala i hoʻohana ʻia i ke kaʻina hana ma waena o 0.006 a me 0.25", me nā ana e hilinaʻi ana i nā mea i hāʻawi ʻia a me ka hoʻohana hope ʻana o ka ʻāpana.

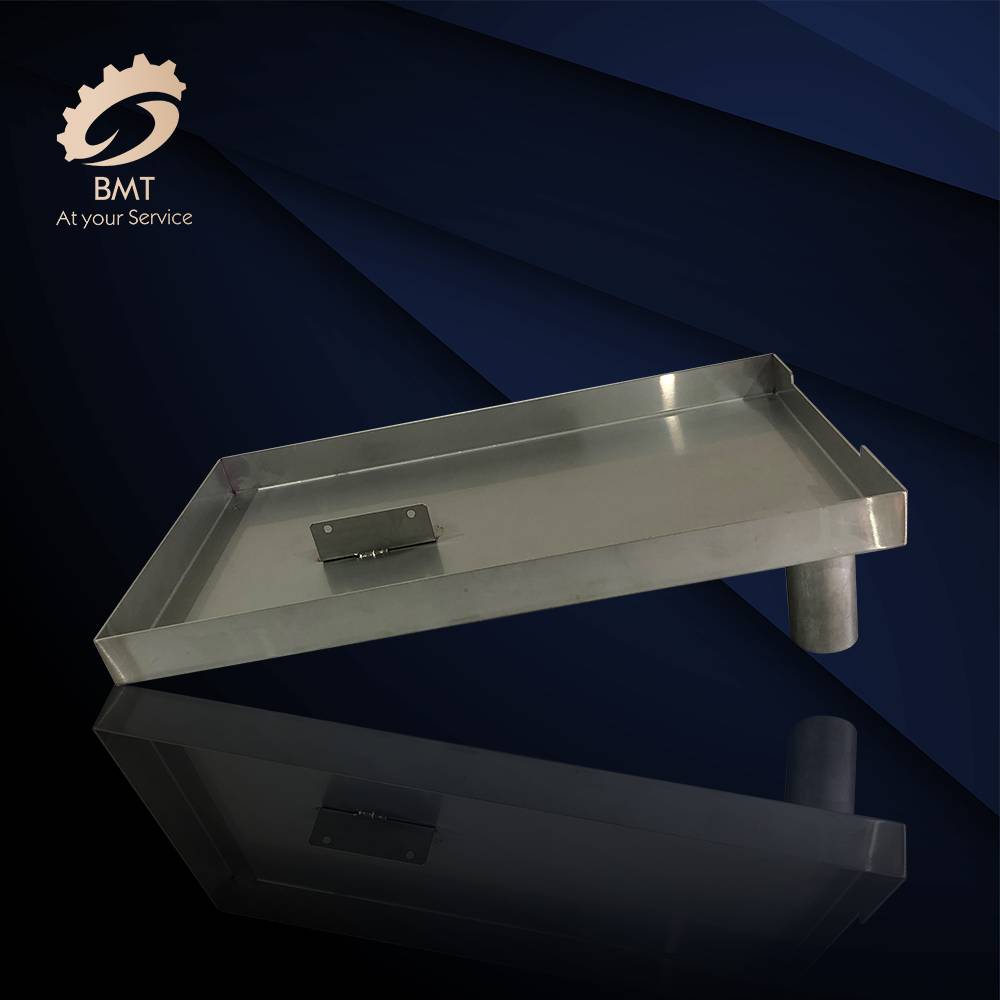

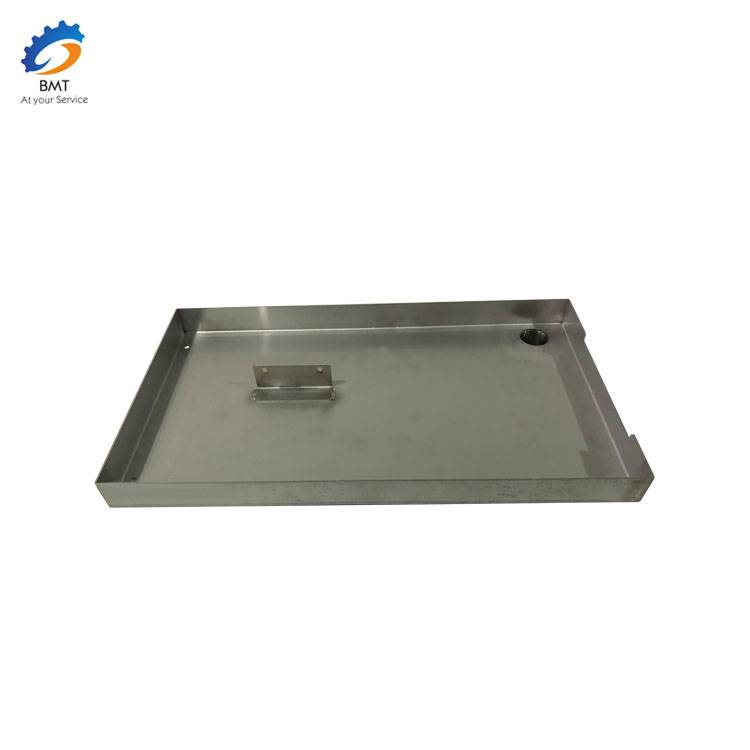

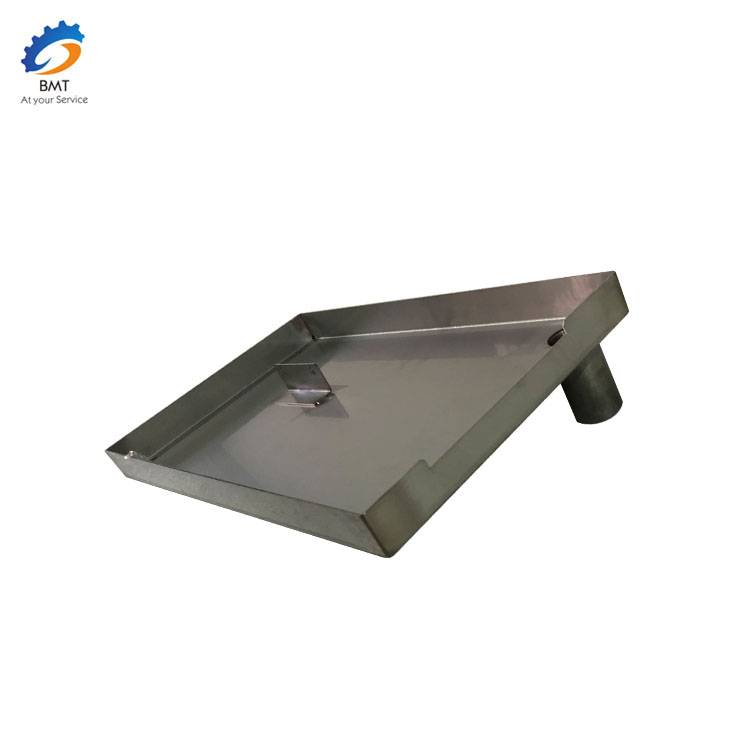

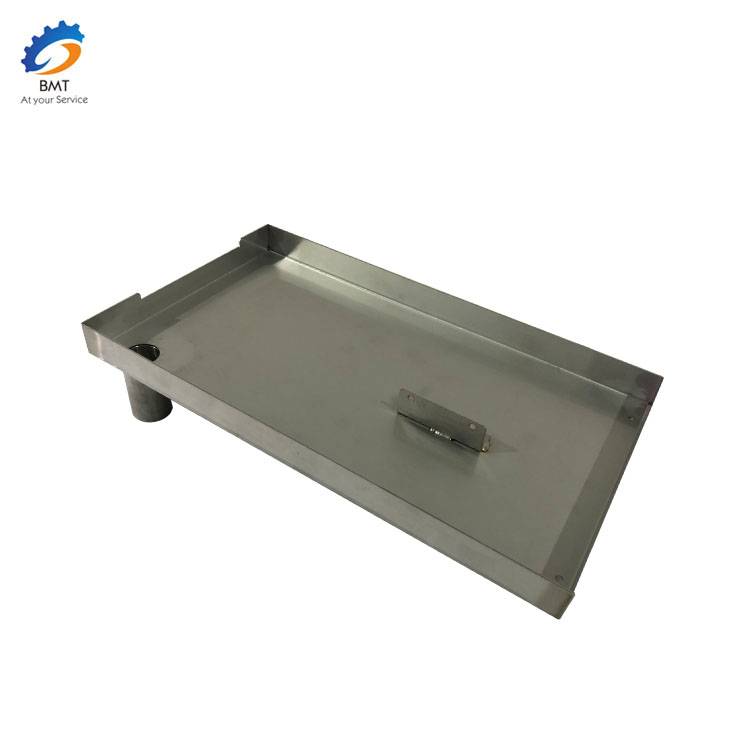

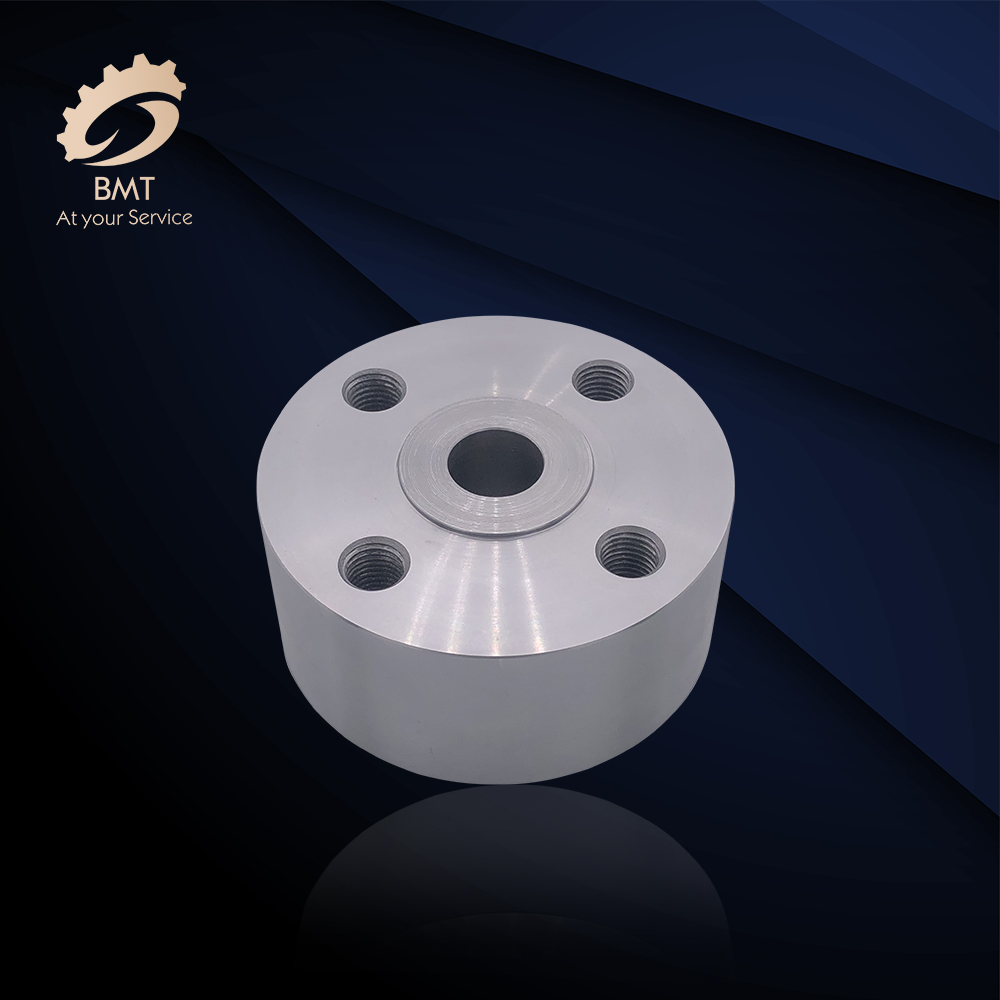

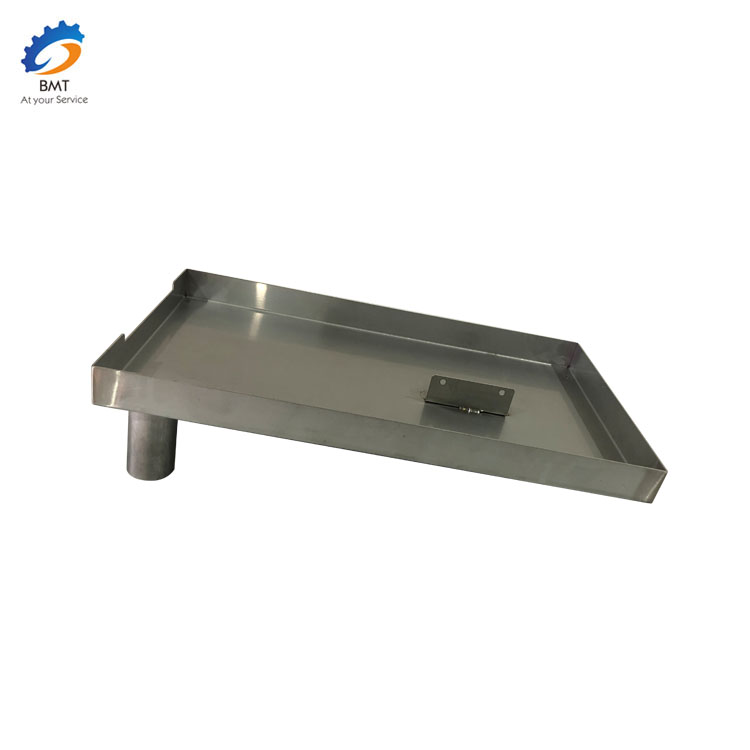

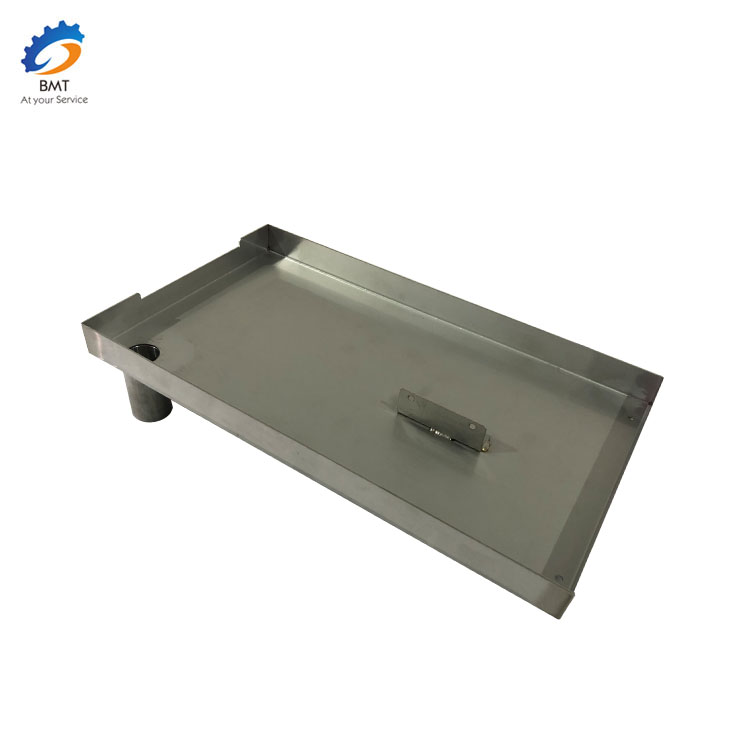

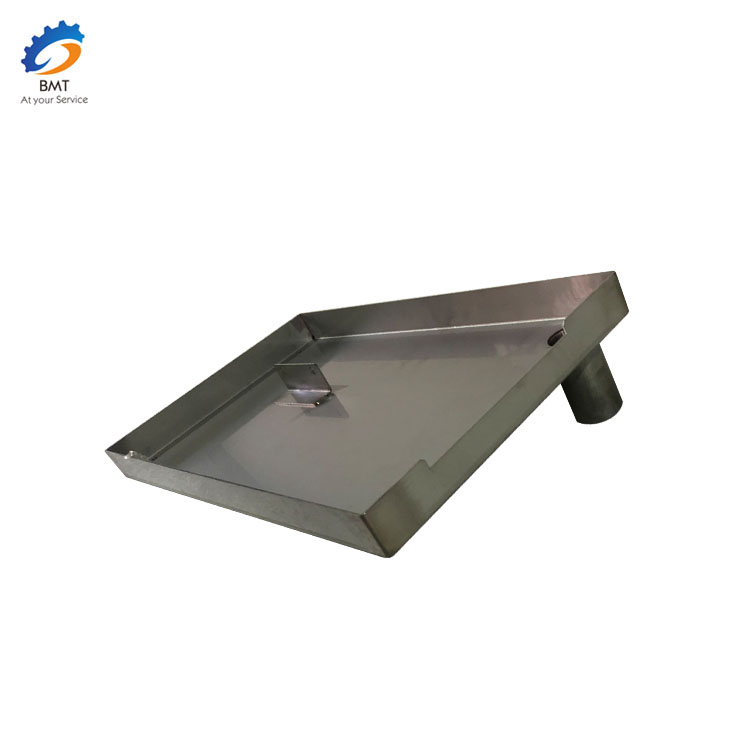

Hōʻike huahana

He ʻokoʻa ka hana ʻana o ka pepa metala ma waena o nā kaʻina hana like ʻole. No kēia kumu, hiki i ka ʻenehana ke hoʻolālā i nā ʻāpana mīkini CNC a i ʻole nā ʻāpana ʻāpana, akā paʻakikī ke hoʻolālā i nā ʻāpana metala.

Ma ka nānā ʻana i nā ʻōlelo aʻoaʻo ʻeono e hiki mai ana, hiki i nā mea hoʻolālā ke hana i nā ʻāpana metala i ikaika, maʻalahi e hana a ʻoi aku ka pale ʻana i ka haki.

1. Puka a me na Kau

No ka mea, hoʻohana pinepine ʻia ka hana ʻana i nā ʻāpana metala no ka hana ʻana i nā pā, nā brackets a me nā mea like, koi pinepine ʻia nā lua a me nā slots no nā screws, bolts a i ʻole nā ʻāpana pili. Hana ʻia nā puka me kahi kuʻi a hoʻopaʻa ʻia i loko o kahi paʻi, e ʻae ai i kahi ʻano pōʻai pololei e ʻoki ʻia mai loko mai o ka metala. Akā inā ʻaʻole i hana pono ʻia nā puka, hiki ke hoʻololi ʻia ka lua a i ʻole nahā ka ʻāpana.

I ke kuʻi ʻana i nā lua i ka lau metala, pono e mālama ʻia kekahi mau lula koʻikoʻi. Pono nā puka he 1/8 "mai kekahi paia a i ʻole ka ʻaoʻao a pono e hoʻokaʻawale ʻia ma ka liʻiliʻi he 6 mau manawa o ka mānoanoa o ka metala. Eia kekahi, pono e kūlike nā anawaena o nā puka a me nā slot a ʻoi aku paha i ka mānoanoa o ka metala.

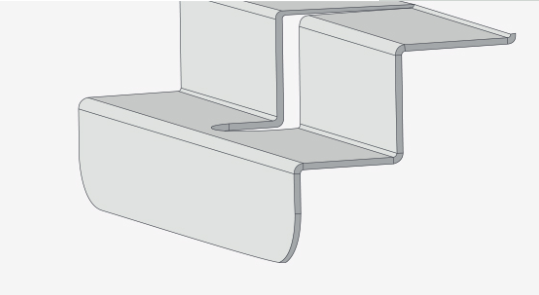

2. Hems

He ala maikaʻi ʻo Hemming e hana i kahi ʻāpana metala palekana a me ka hana. Hana mākou i nā hem hāmama a pani ʻia. Aia ka ʻae ʻana o kahi hem i ka radius o ka hem, ka mānoanoa waiwai, a me nā hiʻohiʻona kokoke i ka hem. Manaʻo mākou e like ka liʻiliʻi o ke anawaena o loko me ka mānoanoa mea, a me ka lōʻihi hoʻihoʻi hem o 6x ka mānoanoa mea.

I ka hoʻohui ʻana i kahi hem i kahi ʻāpana metala, pono e hahai ʻia kekahi mau alakaʻi e hōʻoia i ka hana maikaʻi loa. No ka hoʻomaka, ʻoi aku ka maikaʻi o ka pale ʻana i nā hem i pani ʻia. ʻOi aku ka maikaʻi o nā kuʻekuʻe paʻa i ka pōʻino o ka mea ma muli o ke kihi loa o ka piko, no laila, ʻoi aku ka maikaʻi o ka hāmama ʻana i nā ʻaoʻao ma waena o nā ʻaoʻao ʻelua.

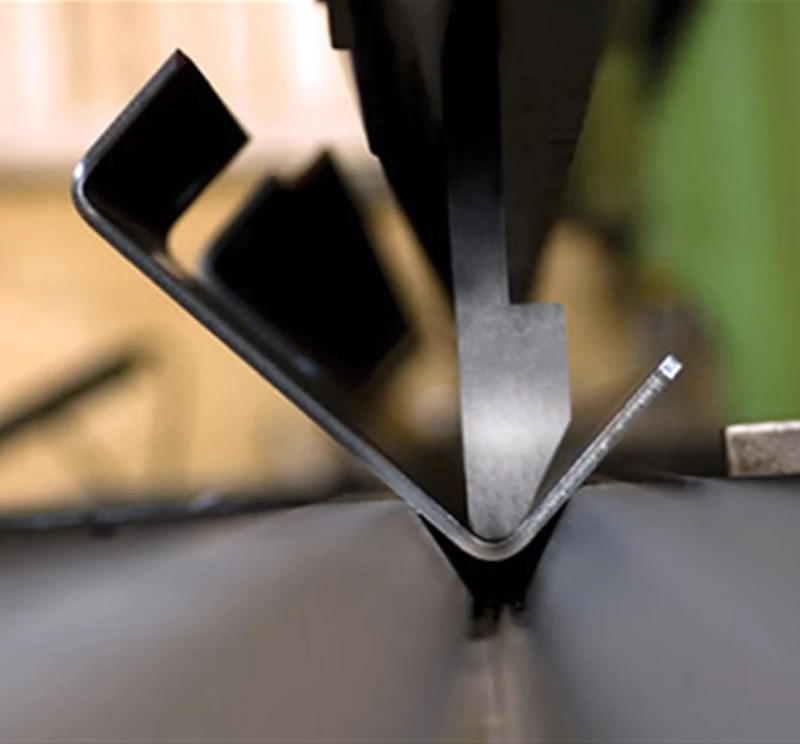

3. Piʻo

ʻO ka piko kekahi o nā kaʻina hana koʻikoʻi i ka hana ʻana i ka metala. Ke hoʻohana nei i nā mea hana e like me nā pahu a me nā mīkini paʻi, hiki i ka hale hana ke hoʻololi i ka metala i nā ʻano hou. No ka kulou, i mea e hōʻoia ai i ka pololei a hiki i ka piko, pono mākou e hahai i kekahi mau lula, a e hoʻemi i ka hiki ke hōʻino i ka mea.

ʻO kekahi lula e hahai ai, ʻo ia, i ka wā e hoʻolālā ai i kahi ʻāpana metala me nā piko, pono e kūlike a ʻoi aku paha ka radius o loko i ka mānoanoa o ka metala e pale aku i ka deformation. Manaʻo ʻia e hoʻohana i ka radius like ma nā piko a pau. ʻO ka mālama ʻana i ke kūlike i ka kuhikuhi ʻana a me ka radius hiki ke kōkua i ka hōʻemi ʻana i nā kumukūʻai, no ka mea ʻaʻole pono e hoʻohuli hou ʻia ka ʻāpana a hiki i nā mea kulou ke hana hou i hoʻokahi kaʻina hana like.

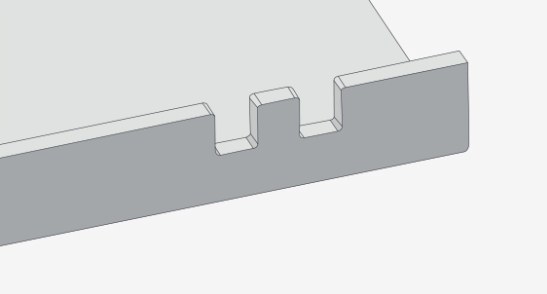

4. Notches a me nā Tabs

ʻO nā notches a me nā tabs nā hiʻohiʻona nui o nā ʻāpana metala e pono ai no ka hoʻohui ʻana i nā wili a i ʻole nā mea hoʻopaʻa a i ʻole no ka hoʻopili ʻana i nā ʻāpana he nui. ʻO nā notches he mau kiko liʻiliʻi ma ka lihi o kahi ʻāpana, ʻoiai ʻo nā ʻaoʻao he mau hiʻohiʻona kūwaho. Hoʻohui pinepine ʻia kahi ʻāpana i loko o kahi ʻāpana metala e hoʻokomo i kahi notch o kahi ʻāpana ʻē aʻe.

E like me nā hiʻohiʻona metala ʻē aʻe, ʻo ka hana ʻana i nā notches kūpono a me nā ʻaoʻao pono e hahai i kekahi mau lula: pono nā notches ma ka liʻiliʻi o ka mānoanoa o ka mea a i ʻole 1mm, ʻoi aku ka nui, a ʻaʻole hiki ke ʻoi aku ma mua o 5 mau manawa o kona laula. Pono nā papa ma ka liʻiliʻi he 2 mau manawa o ka mānoanoa o nā mea a i ʻole 3.2mm, ʻoi aku ka nui, a ʻaʻole hiki ke ʻoi aku ma mua o 5 manawa o kona laula.

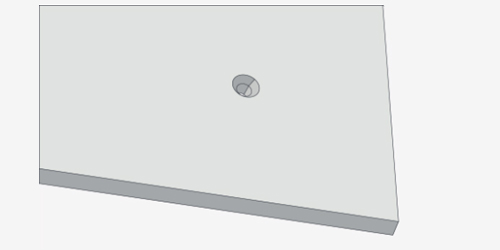

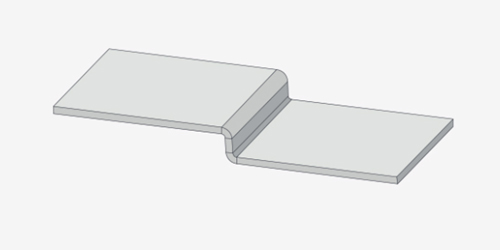

5. Offset a me Countersinks

Hiki ke hana ʻia nā Countersinks e CNC Machining a i hana ʻia e nā mea hana kūikawā. He koʻikoʻi loa ka hoʻomanawanui ʻana no ke anawaena nui countersink, no ka mea pono paha e hoʻohana ʻia me nā wili a i ʻole nā mea paʻa. Hoʻohana ʻia nā offset no ka hana ʻana i nā kiʻi Z-like i nā ʻāpana metala.

6. Hoʻopau

Ma muli o ka noi a me nā mea i hoʻohana ʻia, hiki ke hoʻopau ʻia nā ʻāpana metala me ka bead blasting, anodizing, plating, powder coating a me nā ʻano hana ʻē aʻe, no nā hana hana a i ʻole e hoʻomaikaʻi wale i ke ʻano o ka ʻāpana.