ʻO nā mea hoʻopili Titanium a me Titanium Alloy Forgings

Loaʻa nā pono o ka Titanium a me ka titanium alloys o ka haʻahaʻa haʻahaʻa, ka ikaika kikoʻī kiʻekiʻe a me ke kūpaʻa corrosion maikaʻi, a hoʻohana nui ʻia i nā ʻano āpau.

ʻO ka hana ʻana i ka Titanium kahi ʻano hana e hoʻopili ai i ka ikaika o waho i nā blank metala titanium (Kae ʻole nā papa) e hana i ka deformation plastic, hoʻololi i ka nui, ʻano, a hoʻomaikaʻi i ka hana. Hoʻohana ʻia ia e hana i nā ʻāpana mechanical, nā mea hana, nā mea hana a i ʻole nā pololei. Eia kekahi, e like me ke ʻano o ka neʻe ʻana o ka slider a me nā hiʻohiʻona o ka neʻe ʻana o ka slider (No ka hana ʻana i nā ʻāpana slender, lubrication a me ka hoʻoluʻu ʻana, a me ka hana ʻana i nā ʻāpana hana kiʻekiʻe), hiki ke hoʻonui ʻia nā ʻaoʻao o ka neʻe ʻana. ka hoʻohana ʻana i kahi mea hana uku.

He ʻokoʻa nā ʻano hana i luna, a ʻokoʻa hoʻi ka ikaika forging koi, kaʻina hana, ka nui o ka hoʻohana ʻana i nā mea, ka hoʻopuka, ka hoʻomanawanui dimensional, a me ka lubrication a me nā ʻano hoʻoluʻu. ʻO kēia mau kumu kekahi mau mea e pili ana i ka pae o ka automation.

ʻO ka Forging kahi hana o ka hoʻohana ʻana i ka plasticity o ka metala e loaʻa ai kahi kaʻina hana plastic me kahi ʻano a me nā waiwai o ka blank ma lalo o ka hopena a i ʻole ke kaomi ʻana o ka mea hana. ʻO ke kūlana kiʻekiʻe o ka hoʻoulu ʻana i ka hana ʻana ʻaʻole hiki ke loaʻa wale ke ʻano o nā ʻāpana mechanical, akā hoʻomaikaʻi pū i ka hoʻolālā kūloko o ka mea a hoʻomaikaʻi i nā ʻano mechanical o nā ʻāpana mechanical.

1. Hoʻopaʻa manuahi

Hana ʻia ka hoʻoheheʻe manuahi ʻana ma waena o ʻelua mau mea palahalaha a i ʻole nā molole me ka lua ʻole. ʻO nā mea hana i hoʻohana ʻia i ka forging manuahi he maʻalahi ke ʻano, hiki ke maʻalahi, pōkole i ka pōʻai hana a haʻahaʻa ke kumu kūʻai. Eia nō naʻe, kiʻekiʻe ka ikaika o ka hana, paʻakikī ka hana, haʻahaʻa ka huahana, ʻaʻole kiʻekiʻe ka maikaʻi o nā forgings, a nui ka haʻawina machining. No laila, kūpono wale ia no ka hoʻohana ʻana inā ʻaʻohe koi kūikawā i ka hana o nā ʻāpana a liʻiliʻi ka helu o nā ʻāpana.

2. Open Die Forging (Die Forging with Burrs)

Hoʻololi ʻia ka blank ma waena o ʻelua mau modula me nā lua i kahakaha ʻia, paʻa ka hoʻopaʻa ʻana i loko o ka lua, a kahe ka metala keu mai ka ʻāpana haiki ma waena o nā make ʻelua, e hana ana i nā burrs a puni ka forging. Ma lalo o ke kū'ēʻana o ka mold a me nā burrs a puni, ua koiʻia ka metala e paʻiʻia i keʻano o ka lua.

3. Hoʻopaʻa ʻia ʻo Die Forging (Die Forging without Burrs)

I ka wā o ke kaʻina hana hoʻopaʻa ʻana i ka make, ʻaʻole i hoʻokumu ʻia nā burrs transverse perpendicular i ke kuhikuhi o ka neʻe ʻana o ka make. ʻElua mau hana o ka lua o ka make forging paʻa: hoʻokahi no ka hana ʻana i ka blank, a ʻo kekahi no ke alakaʻi.

4. Extrusion Die Forging

Ke hoʻohana nei i ke ʻano extrusion no ka make forging, ʻelua ʻano o ka forging, extrusion i mua a me reverse extrusion. Hiki i ka extrusion die forging ke hana i nā ʻāpana ʻokoʻa a me nā ʻāpana paʻa, a hiki ke loaʻa i nā forgings me ka precision geometrical kiʻekiʻe a me ke ʻano o loko.

5. Multi-Directional Die Forging

Lawe ʻia ia ma kahi mīkini hoʻoheheʻe multi-directional. Ma waho aʻe o ke kuʻi kuʻi a me ka hoʻopili ʻana i ka plug, ʻo ka multi-directional die forging machine ʻelua pū kekahi plungers ākea. Hiki ke hoʻohana ʻia kona ejector no ke kuʻi ʻana. ʻOi aku ka kiʻekiʻe o ke kaomi o ka ejector ma mua o ke kaomi hydraulic maʻamau. E nui. I ka multi-directional die forging, hana ka slider a me ka hui pū ʻana ma luna o ka mea hana mai ka ʻaoʻao kū pololei a me ka ʻaoʻao, a hoʻohana ʻia hoʻokahi a ʻoi aku paha nā punches perforation e hoʻokahe i ka metala i waho mai ke kikowaena o ka lua e hoʻokō ai i ke kumu o ka hoʻopiha ʻana i ka pahu. lua.

6. Māhele Māhele

No ka hana ʻana i nā forgings nui nui ma ke kaomi hydraulic e kū nei, hiki ke hoʻohana ʻia nā ʻano hana hoʻokalakupua e like me ka māhele make a me ka shim plate die forging. ʻO ka hiʻohiʻona o ke kaʻina hana hoʻoheheʻe ʻāpana, ʻo ia ka hana ʻana i ka ʻāpana forging i kēlā me kēia ʻāpana, e hana ana i hoʻokahi ʻāpana i ka manawa, no laila hiki ke liʻiliʻi loa ka tonnage mea pono. ʻO ka ʻōlelo maʻamau, hiki ke hoʻohana ʻia kēia ʻano hana no ka hana ʻana i nā forgings nui ma nā kaomi hydraulic medium-sized.

7. Hoʻopaʻa ʻana i ka Isothermal Die Forging

Ma mua o ka hoʻopaʻa ʻana, ua hoʻomehana ʻia ka ʻōpala i ka mahana forging o ka blank, a ʻo ka mahana o ka mold a me ka blank e mau nō ia i loko o ke kaʻina hana forging, i hiki ke loaʻa ka nui o ka deformation ma lalo o ka hana o kahi ikaika deformation liʻiliʻi. . Ua like loa ka hana ana i ka isothermal a me ka isothermal superplastic die forging.

Hoʻohana nui ʻia ke kaʻina hana forging Titanium alloy i ka mokulele a me ka hana aerospace (Kaʻina hana hoʻoheheʻe Isothermal Die Forgingua hoʻohana ʻia i ka hana ʻana i nā ʻāpana ʻenekini a me nā ʻāpana hoʻolālā mokulele), a ke lilo nei ia i mea kaulana loa i nā ʻoihana ʻoihana e like me nā kaʻa, ka mana uila, a me nā moku.

I kēia manawa, ʻoi aku ka kiʻekiʻe o ke kumukūʻai hoʻohana o nā mea titanium, a ʻaʻole i ʻike piha nā māla kīwila i ka nani o nā alloys titanium. Me ka holomua o ka ʻepekema, ʻoi aku ka maʻalahi o ka hoʻomākaukau ʻana i ka ʻenehana huahana titanium a me ka titanium alloy a e haʻahaʻa a haʻahaʻa ke kumukūʻai o ka hana, a e hōʻike ʻia ka nani o nā huahana titanium a me ka titanium alloy i kahi ākea ākea.

UsiʻO ke ʻano extrusion no ka make forging, ʻelua ʻano o ka forging, Forward Extrusion a me Reverse Extrusion. Hiki i ka Extrusion Die Forging ke hana i nā ʻāpana ʻokoʻa a me nā ʻāpana paʻa, a hiki ke loaʻa i nā forgings me ke kiʻekiʻe geometrical precision a me ka denser internal structure.

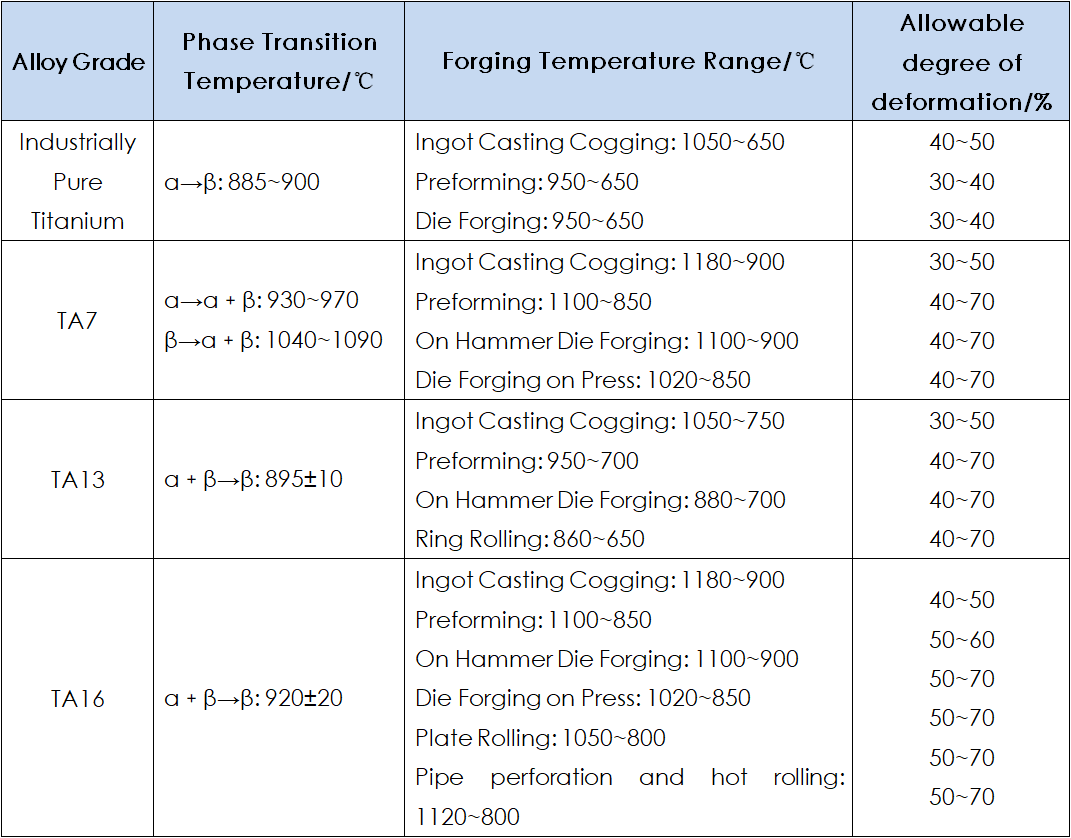

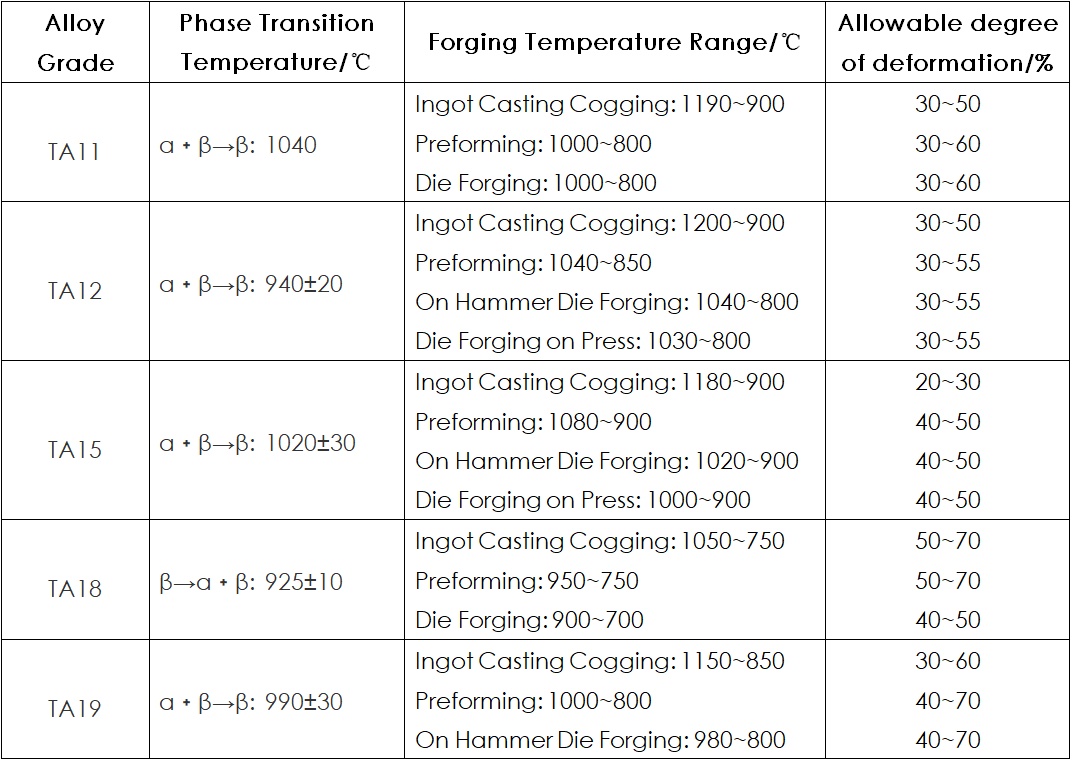

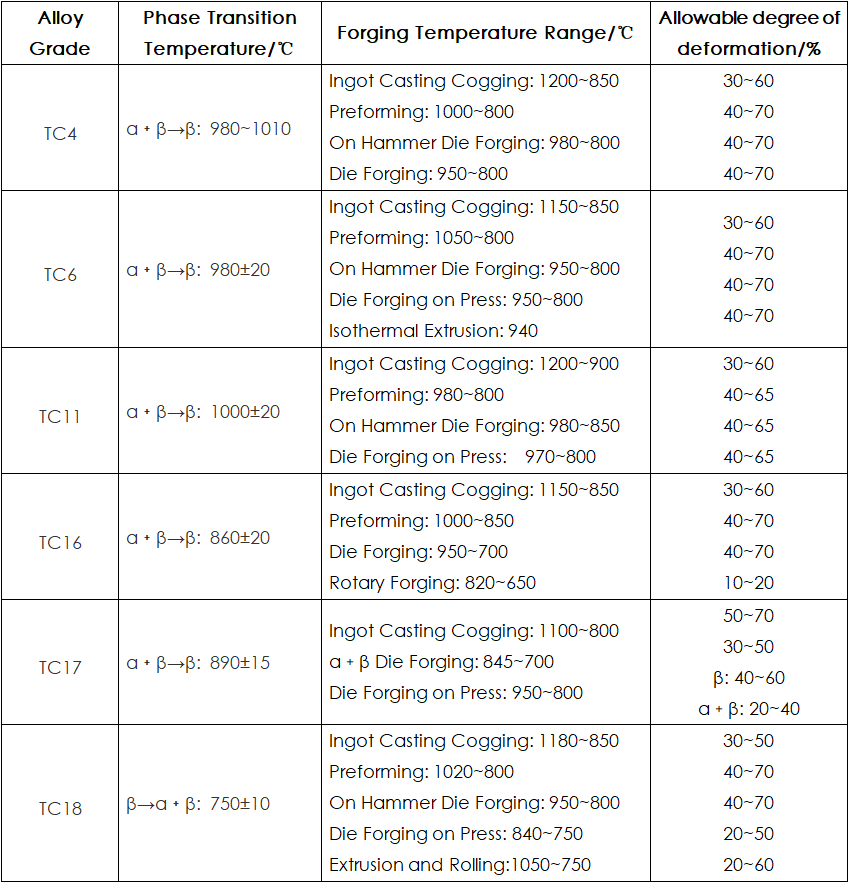

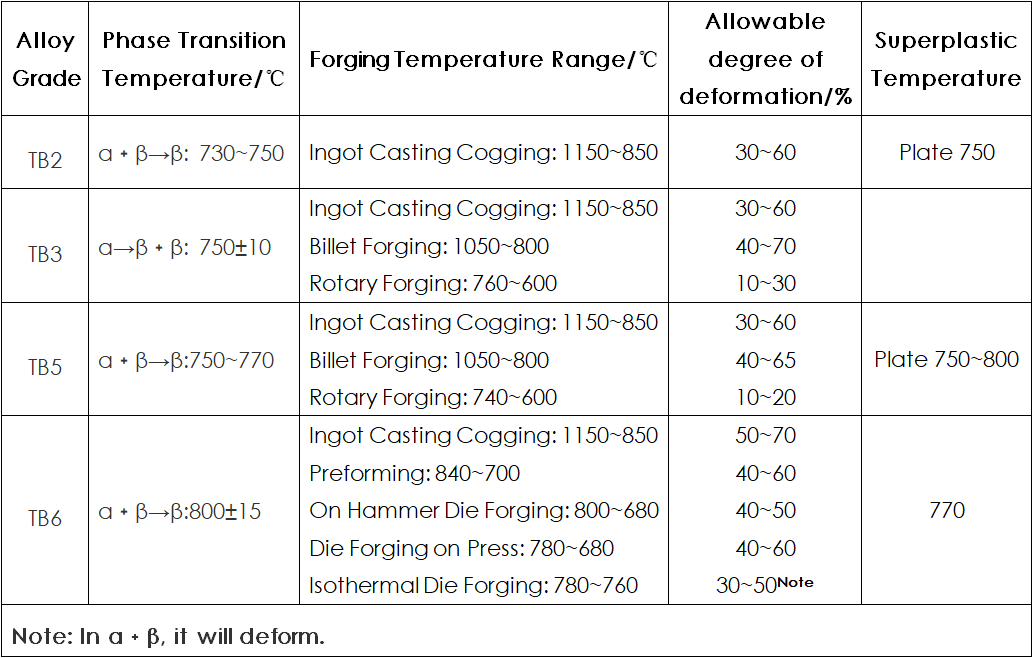

Wahi a ka noiʻi a me ka ʻike hana hale hana, ua hōʻuluʻulu ʻia ka ʻikepili hana forging kaʻina hana o α-type, near-α-type, α﹢β-type a me kokoke-β-type titanium alloys i ka Papa 1 a hiki i ka Papa 4.

Mai ka ʻikepili ma ka Papa 1 a hiki i ka Papa 4, hiki ke ʻike ʻia ʻo ka nui o ka hoʻopili ʻana o ka nui o ka titanium alloy ingots i loko o ka laulā o 1150 ° C a 1200 ° C, a ʻo ka wela forging mua o kekahi mau ingots titanium alloy aia i ka laulā. o 1050°C a hiki i 1100°C; Aia kēia mau ʻāpana wela ʻelua i loko o ka pae ʻāpana β, a ʻoi aku ka kiʻekiʻe o ka mua ma mua o ka mahana hoʻololi o ka pae no nā kumu he nui.

ʻO ka mea mua, he kiʻekiʻe ke kiʻekiʻe o ka alloy a me ke kūpaʻa deformation haʻahaʻa i ka pae ʻāpana β. I mea e hoʻoikaika ai i ka manawa forging lōʻihi, He mea pono e hoʻomaikaʻi i ka huahana; ʻO ka lua, ʻo ka billet no ka ulu ʻana o ka ingot i hāʻawi nui ʻia ma ke ʻano he blank no ka forging. Ma hope o ka forging me ka nui o ka deformation, hiki ke hoʻomaikaʻi ʻia ke ʻano me ka ʻole o ka hoʻopili ʻana i ka hana o ka forging. No laila, koho ʻia kahi kaʻina hana me ka huahana kiʻekiʻe.

Mai ka ʻikepili ma ka Papa 1 a hiki i ka Papa 4, hiki ke ʻike ʻia ʻaʻole ʻoi aku ka haʻahaʻa o ka wela forging mua o ka make forging ma luna o ka paʻi ma mua o ka wela forging mua o ka billet ingot, akā ʻoi aku ka haʻahaʻa ma mua o ka mahana hoʻololi α/β. e 30 ℃ ~ 50 ℃. ʻO ka hapa nui o ka titanium ʻO ka mahana hoʻoheheʻe make o ka alloy aia ma ka laulā o 930 ℃ ~ 970 ℃, ʻo ia ka mea e hōʻoia i ka deformation ma ka māhele α﹢β e loaʻa ai ka microstructure a me nā waiwai o ka forging. No ka mea e pono ana i ka hammer die forging he mau puʻu a he lōʻihi ka manawa hana, hiki ke hoʻonui ʻia ka mahana wela o ka hoʻopaʻa ʻana i hoʻopau ʻia e 10 ℃ ~ 20 ℃ ma mua o ka paʻi paʻi. Eia naʻe, i mea e hōʻoiaʻiʻo ai i ka hana a me ka mechanical waiwai o ka titanium alloy pau forgings, No laila, i ka hopena forging wela o ka forging kaʻina hana pono e hoomaluia ma ka α﹢β elua-phase māhele.

Hiki ke ʻike ʻia mai ka ʻikepili ma ka Papa 1 a hiki i ka Papa 4 ʻoi aku ka kiʻekiʻe o ka wela forging mua o ka hapa nui o ka titanium alloy preforms ma mua a kokoke paha i ka mahana hoʻololi. ʻO ka α/β forging wela mua o ke kaʻina hana hoʻololi e like me ka preforming ʻoi aku ka haʻahaʻa ma mua o ka wela o ka mohala ʻana o ka ingot, a ʻoi aku ka kiʻekiʻe ma mua o ka mahana forging mua o ka forging make. ʻO ka deformation ma kēia wahi wela ʻaʻole mālama wale i ka huahana, akā hoʻomākaukau pū kekahi i kahi hoʻolālā maikaʻi no ka forging.

Papa 1 Ke hoʻopaʻa nei i ka ʻikepili hana o ka α-type titanium

Pākuʻi 2 Kaʻina hana hoʻopaʻa i ka ʻikepili hana kokoke i ka α-type titanium alloy

Pākuʻi 3 Ka hoʻopaʻa ʻana i ka ʻikepili hana o α﹢β titanium huila

Papa 4 Kaʻina hana hoʻopaʻa i ka ʻikepili hana kokoke i ka β-type titanium alloy

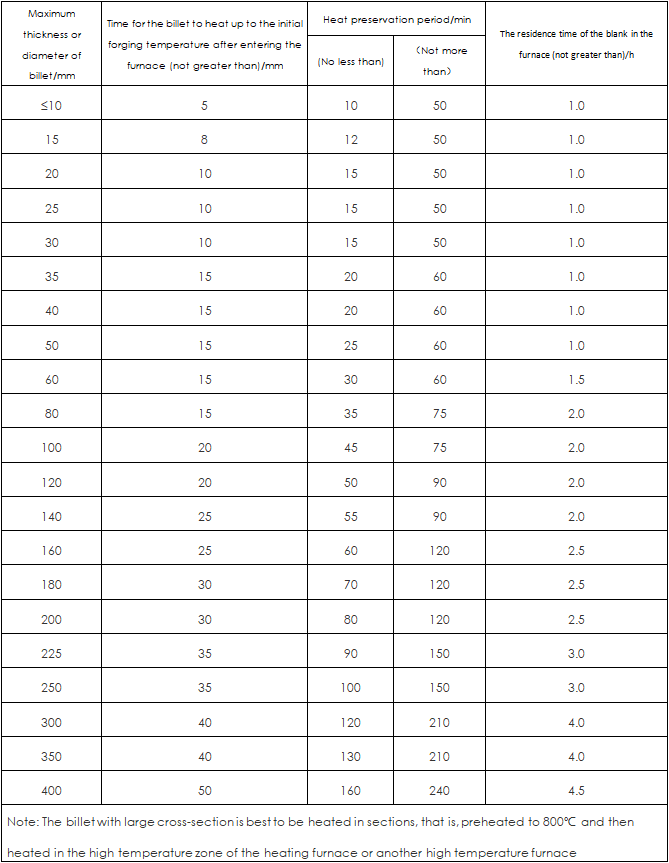

Papa 5 Hoʻomaʻamaʻa a me ka manawa paʻa o nā pani hakahaka titanium

Hoʻokumu ʻia ʻo BMT i ka hana ʻana i ka titanium forging premium a me ka titanium alloy forging e hōʻike ana i ka mana mechanical maikaʻi loa, tenacity, corrosion resistance, low density and high intensity. ʻO ka hana maʻamau a me ke kaʻina ʻike ʻana o nā huahana BMT titanium ua lanakila i ka paʻakikī ʻenehana a me ka paʻakikī o ka mīkini ʻana o ka hana ʻana i ka titanium forging.

Hoʻokumu ʻia ka hana kiʻekiʻe kiʻekiʻe titanium forging ma luna o ka hoʻolālā kaʻina hana ʻoihana a me ke ʻano holomua holomua. Hiki ke hoʻopili ʻia ka BMT titanium forging i ka laulā mai ka ʻili liʻiliʻi e kākoʻo ana i ka hale a hiki i ka nui o ka titanium forging no nā mokulele.

Hoʻohana nui ʻia ka BMT titanium forgings i nā ʻoihana he nui, e like me ka aerospace, offshore engineering, oil and gas, sports, food, automobile, etc. ʻO kā mākou hana hana makahiki a hiki i 10,000 tons.

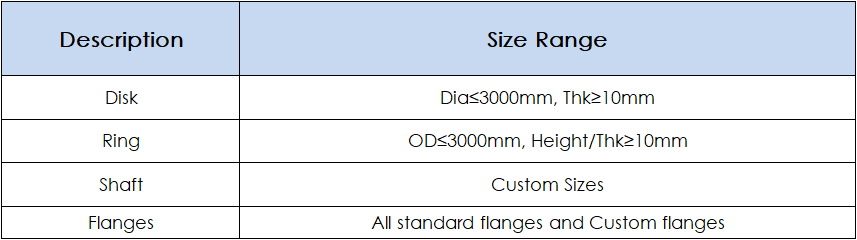

Laulā nui:

Loaʻa Mea Kimia Hui

Loaʻa Mea Kimia Hui

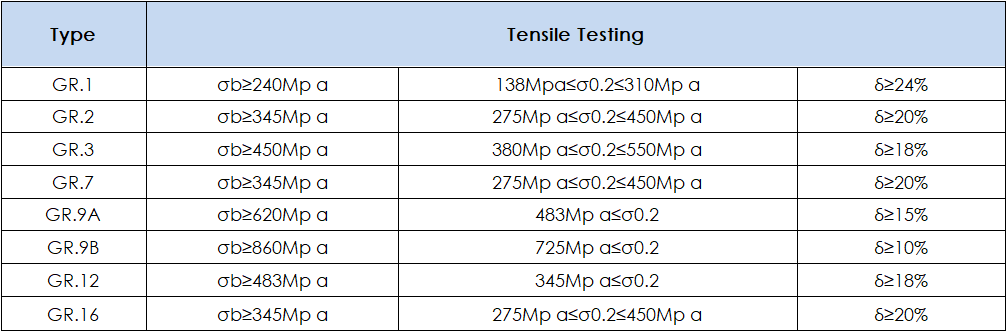

Hoʻāʻo nānā:

- ʻIkepili Kimia

- Hoao Mechanical Property

- ʻO ka hoʻāʻo ʻana

- Hoʻāʻo ʻana i ke ahi

- Ho'āʻo palahalaha

- Ho'āʻo Kulou

- Ho'āʻo Hydro-Static

- Ho'āʻo Pneumatic (Ho'āʻo i ke ea ma lalo o ka wai)

- NDT hoao

- Eddy-I kēia manawa

- Ho'āʻo Ultrasonic

- Hoao LDP

- Hoao Ferroxyl

Huahana (Max a me Min nui o ke kauoha):palena ʻole, e like me ke kauoha.

Ka manawa o waena o ka hoʻomaka a i ka wā pau:ʻO ka manawa alakaʻi maʻamau he 30 mau lā. Eia naʻe, pili ia i ka nui o ke kauoha accrdingly.

Kaʻahele:ʻO ke ala maʻamau o ka lawe ʻana ma ke Kai, ma ka Air, ma Express, ma Train, e koho ʻia e nā mea kūʻai.

Hoʻopili:

- E pale ʻia nā ʻaoʻao o ka paipu me ka plastic a i ʻole ka pahu pahu.

- Hoʻopili ʻia nā mea pono a pau e pale i nā welau a me ke alo.

- Hoʻopili ʻia nā waiwai ʻē aʻe a pau e nā pad foam a me nā pahu plastik pili a me nā pahu plywood.

- Pono pono kēlā me kēia lāʻau i hoʻohana ʻia no ka hoʻopili ʻana i mea e pale ai i ka hoʻohaumia ʻana ma o ka hoʻopili ʻana me nā lako hana.