Papa Titanium, Pepa a me ka Coil

Ke Kaʻina Hana Hana Papa Titanium

Wela Forging He kaʻina forging kahi e hoʻolāʻau hou ʻia ai ka metala ma luna o ka mahana.ʻO ka ʻōwili wela ʻO ke kaʻina o ka ʻōwili ʻana i nā mahana ma luna o ka recrystallization.ʻO ke kaʻina ʻōwili anuanu kahi haʻahaʻa haʻahaʻa o ka mahana deformation plastic ma mua o ka mahana hoʻihoʻi.

Hoʻopili: Kaʻina hana e hoʻomehana mālie ʻia nā metala i kekahi mahana, no ka manawa kūpono, a laila hoʻomālili (maʻa mālie a hoʻomalu ʻia i kekahi manawa) ma kahi kūpono kūpono.

Pickling: E hoʻokomo i ka huahana i loko o ka wai wai, e like me ka sulfuric acid, e wehe i nā oxides a me nā kiʻi ʻoniʻoni ʻē aʻe ma luna o ka metala.

Nā hiʻohiʻona o ka pā titanium

1. ʻO ka pā hua Titanium he kiʻiʻoniʻoni oxidized ma ka ʻili, e like me kahi mea hoʻokaʻawale lauoho maikaʻi. ʻO ka hoʻohana ʻana i ka pā hua titanium e mālama i ka mea hoʻokaʻawale, e maʻalahi ka ʻili o ka pā, e hoʻopau i ke kaʻina o ka preprocessing o ka pā hua, a ʻoi aku ka māmā o ka pā hua titanium ma mua o ka pā hua keleawe.

2. ʻO ke ola lawelawe o ka pā hua titanium ma mua o 3 mau manawa o ka pā hua keleawe, hiki ke hiki i 10 a 20 mau makahiki e like me nā kūlana hana.

3. ʻO ke keleawe electrolytic i hana ʻia mai ka pā hua titanium he ʻano aniani aniani paʻa, ʻili maʻemaʻe a maikaʻi loa.

4. No ka mea, ʻaʻole pono e uhi ʻia ka pā titanium me ka mea hoʻokaʻawale, hiki iā ia ke pale i ka haumia o ka electrolyte keleawe.

5. E hoʻomaikaʻi i ka hiki ke hana a hoʻemi i ke kumukūʻai hana o ke keleawe electrolytic, i mea e loaʻa ai nā pono waiwai maikaʻi.

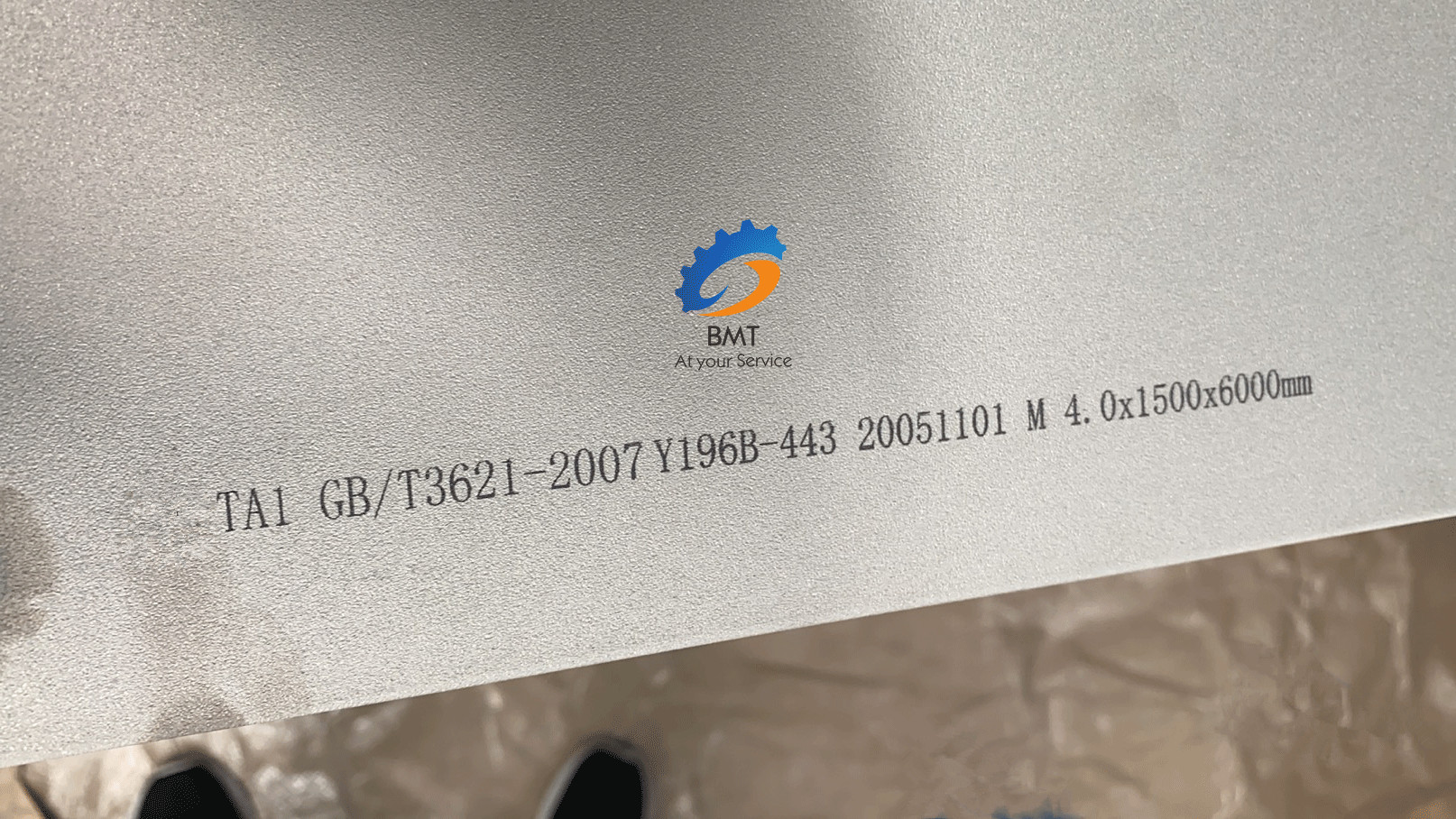

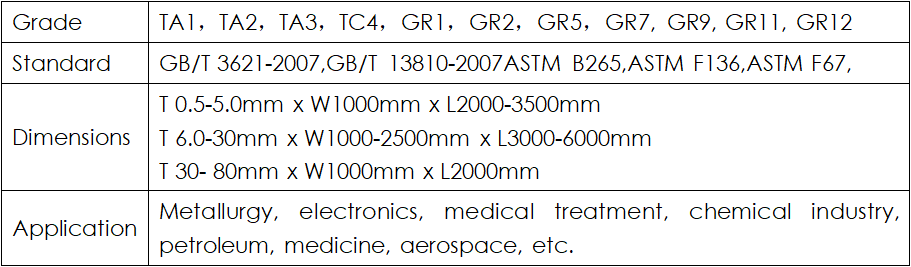

Hana ʻia ka laulā BMT o ka pepa titanium a me ka pā e like me nā kūlana e like me ASTM/ASME B/SB265, ASTM F136, ASTM F67, AMS 4911, a me AMS4900.

He 10000 tons ka hana makahiki a BMT no ka PHE (Plate for heat exchanger), a me 8000 tons no nā noi ʻē aʻe. ʻO nā ʻāpana titanium kiʻekiʻe kiʻekiʻe o BMT, me nā ʻāpana titanium i ʻōwili ʻia a me nā pā titanium ʻōwili wela, aia ma lalo o ka mākaʻikaʻi ʻana a nānā i nā huaʻōlelo o ka mea maka-titanium sponge. Mālama ʻo BMT i ke kaʻina hana holoʻokoʻa, e like me ka hoʻoheheʻe ʻana, forging, hot rolling, cold rolling, heat treatment, etc. Hoʻopuka mākou i nā huahana a puni ka honua a hoʻokipa maikaʻi iā ʻoe e hui pū me mākou.

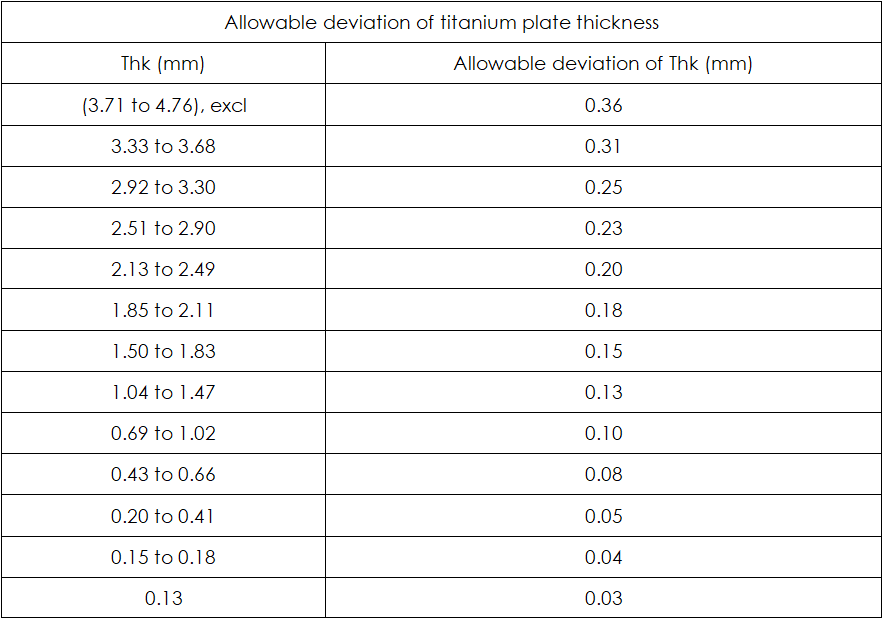

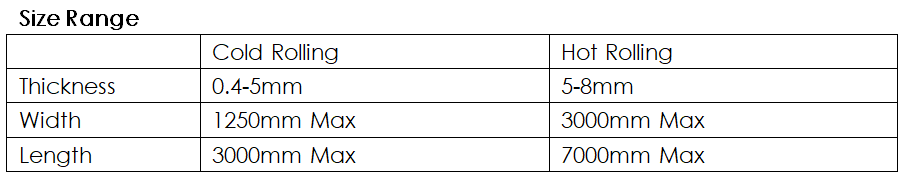

ʻAe ʻia ka ʻae ʻia ʻana o ka mānoanoa o ka pā Titanium:

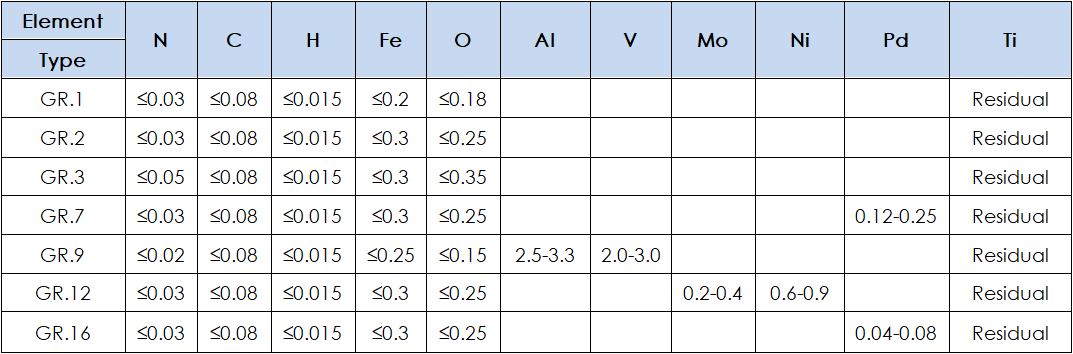

Loaʻa i nā mea hana kemika:

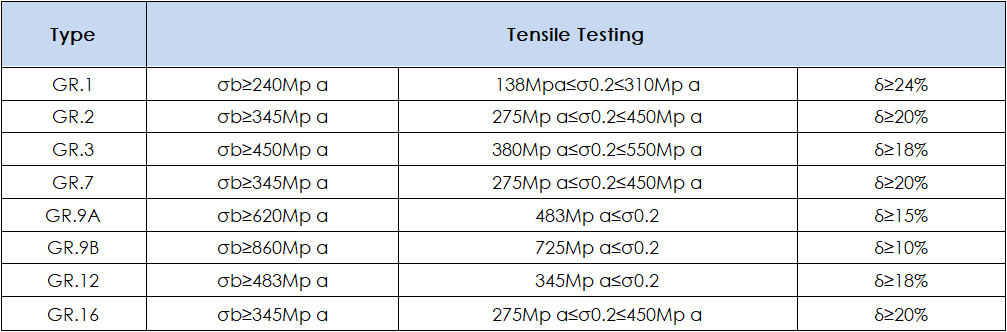

Mea Loaʻa Mechanical Property:

Hoʻāʻo nānā:

- ʻIkepili Kimia

- Hoao Mechanical Property

- ʻO ka hoʻāʻo ʻana

- Hoʻāʻo ʻana i ke ahi

- Ho'āʻo palahalaha

- Ho'āʻo Kulou

- Ho'āʻo Hydro-Static

- Ho'āʻo Pneumatic (Ho'āʻo i ke ea ma lalo o ka wai)

- NDT hoao

- Eddy-I kēia manawa

- Ho'āʻo Ultrasonic

- Hoao LDP

- Hoao Ferroxyl

Huahana (Max a me Min nui o ke kauoha):palena ʻole, e like me ke kauoha.

Ka manawa o waena o ka hoʻomaka a i ka wā pau:ʻO ka manawa alakaʻi maʻamau he 30 mau lā. Eia naʻe, pili ia i ka nui o ke kauoha accrdingly.

Kaʻahele:ʻO ke ala maʻamau o ka lawe ʻana ma ke Kai, ma ka Air, ma Express, ma Train, e koho ʻia e nā mea kūʻai.

Hoʻopili:

- E pale ʻia nā ʻaoʻao o ka paipu me ka plastic a i ʻole ka pahu pahu.

- Hoʻopili ʻia nā mea pono a pau e pale i nā welau a me ke alo.

- Hoʻopili ʻia nā waiwai ʻē aʻe a pau e nā pad foam a me nā pahu plastik pili a me nā pahu plywood.

- Pono pono kēlā me kēia lāʻau i hoʻohana ʻia no ka hoʻopili ʻana i mea e pale ai i ka hoʻohaumia ʻana ma o ka hoʻopili ʻana me nā lako hana.