ʻO nā pilikia o ka mīkini Titanium

He liʻiliʻi ka conductivity thermal o ka titanium alloy, no laila ke kiʻekiʻe loa ka ʻoki ʻana i ka wā e hoʻoili ai i ka titanium alloy. Ma lalo o nā kūlana like, ʻoi aku ka nui o ka ʻoki ʻana o ka hana TC4 [i] ma mua o ka pālua o ke kila No. Hoʻokuʻu; liʻiliʻi ka wela kūikawā o ka titanium alloy, a piʻi koke ka mahana kūloko i ka wā o ka hana. No laila, kiʻekiʻe loa ka mahana o ka mea hana, ʻoi aku ka maikaʻi o ka piko o ka mea hana, a ua hoʻemi ʻia ke ola lawelawe.

ʻO ka modulus haʻahaʻa haʻahaʻa o ka titanium alloy [ii] e hana i ka ʻili mīkini i ka springback, ʻoi aku ka nui o ka hana ʻana i nā ʻāpana ʻāpana ʻeleʻele, ʻoi aku ka maʻalahi o ka hoʻoulu ʻana i ka hakakā ikaika ma waena o ka ʻaoʻao a me ka ʻili mīkini. ʻokiʻoki. pahi.

ʻO ka Titanium alloy he hana kemika ikaika, a he maʻalahi ke launa pū me ka oxygen, hydrogen a me ka nitrogen i ke kiʻekiʻe wela, e hoʻonui ai i kona ikaika a hoʻemi i kona plasticity. ʻO ka papa waiwai o ka oxygen i hoʻokumu ʻia i ka wā hoʻomehana a me ka hoʻopaʻa ʻana e paʻakikī i ka mīkini.

Nā loina mīkini o nā mea hao titanium [1-3]

I ke kaʻina hana machining, ʻo ka mea hana i koho ʻia, nā kūlana ʻokiʻoki a me ka manawa ʻokiʻoki e hoʻopili i ka pono a me ka hoʻokele waiwai o ka ʻoki ʻana o ka titanium alloy.

1. E koho i kahi mea paahana kūpono

E like me nā waiwai, nā kaʻina hana a me ka hoʻoponopono ʻana i nā kūlana ʻenehana o ka titanium alloy material, pono ke koho pono ʻia nā mea hana. Pono e koho ʻia ka mea hana maʻamau, ke kumu kūʻai haʻahaʻa, ke kūpaʻa maikaʻi o ka ʻaʻahu, ka paʻakikī wela kiʻekiʻe, a ua lawa ka paʻakikī.

2. E hoʻomaikaʻi i nā kūlana ʻoki

ʻOi aku ka maikaʻi o ka rigidity o ka mīkini-fixture-tool system. Pono e hoʻoponopono maikaʻi ʻia ka hoʻomaʻemaʻe ʻana o kēlā me kēia ʻāpana o ka mīkini, a liʻiliʻi ka holo ʻana o ka radial o ka spindle. Pono e paʻa a paʻa pono ka hana pipili o ka mea paʻa. ʻO ka ʻāpana ʻokiʻoki o ka mea hana e like me ka pōkole, a e hoʻonui ʻia ka mānoanoa o ka ʻoki ʻoki e like me ka hiki ke lawa ka ʻae ʻana o ka chip e hoʻomaikaʻi i ka ikaika a me ka rigidity o ka mea paahana.

3. Hoʻomaʻamaʻa wela kūpono o ka mea i hana ʻia

Hoʻololi ʻia nā waiwai a me ke ʻano metallographic o nā mea hao titanium e ka mālama wela [iii], i mea e hoʻomaikaʻi ai i ka machinability o nā mea.

4. E koho i ka nui oki kupono

Pono e haʻahaʻa ka māmā holo ʻoki. Ma muli o ka hopena nui o ka wikiwiki o ka ʻoki ʻana i ka mahana o ka ʻoki ʻoki, ʻoi aku ka kiʻekiʻe o ka wikiwiki o ka ʻoki ʻana, ka piʻi ʻoi aku o ka mahana o ka ʻoki ʻoki, a me ka mahana o ka ʻoki ʻoki e pili pono i ke ola o ka mea hana, no laila. pono e koho i ka wikiwiki oki kupono.

E hoʻouna i kāu leka iā mākou:

-

Aluminum CNC Mīkini Māhele

-

Hana Metala Aluminum

-

ʻAxis High Precision CNC Machining Parts

-

Nā ʻāpana mīkini CNC no Italia

-

ʻO nā ʻāpana alumini CNC Machining

-

Mīkini ʻāpana Kaʻa

-

ʻO nā mea hoʻoheheʻe Titanium Alloy

-

ʻO nā mea hoʻopili Titanium a me Titanium Alloy

-

ʻO nā mea hoʻopili Titanium a me Titanium Alloy Forgings

-

ʻO nā uwea huila Titanium a me Titanium

-

Nā Bara Titanium

-

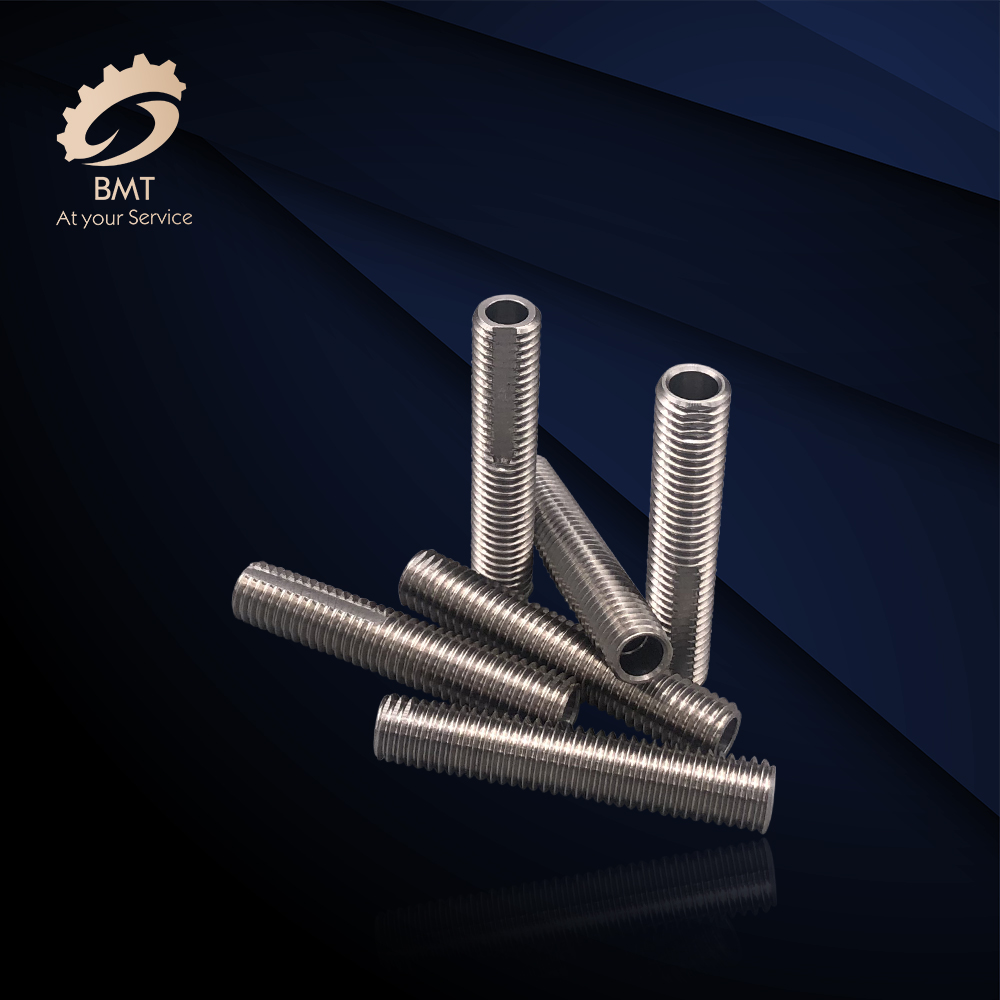

ʻO nā paipu hili ʻole Titanium

-

ʻO nā paipu welded Titanium