ʻO nā uwea huila Titanium a me Titanium

ʻO ka titanium maʻemaʻe he metala keʻokeʻo keʻokeʻo, nona nā waiwai maikaʻi loa. ʻO ka nui o ka Titanium he 4.54g/cm3, 43% ʻoi aku ka māmā ma mua o ke kila a ʻoi aku ke kaumaha ma mua o ka magnesium metala māmā hanohano. Akā ʻo ka ikaika mechanical e like me ke kila, ʻelua ʻoi aku ka ikaika o ka alumini a ʻelima mau manawa ʻoi aku ka ikaika ma mua o ka magnesium. Kūpaʻa ʻo Titanium i ka wela kiʻekiʻe a loaʻa kahi helu heheʻe o 1942K, kokoke 1000K kiʻekiʻe ma mua o ke gula a kokoke 500K kiʻekiʻe ma mua o ke kila.

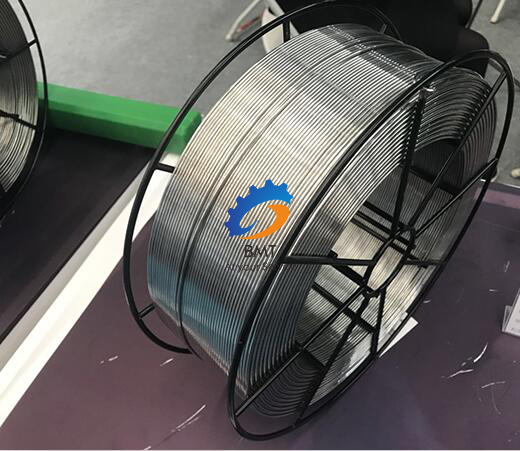

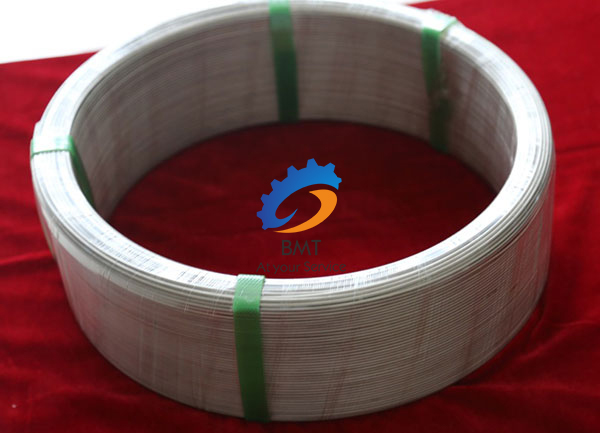

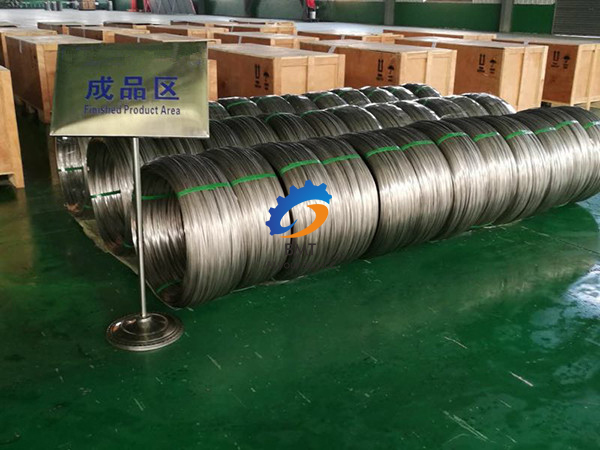

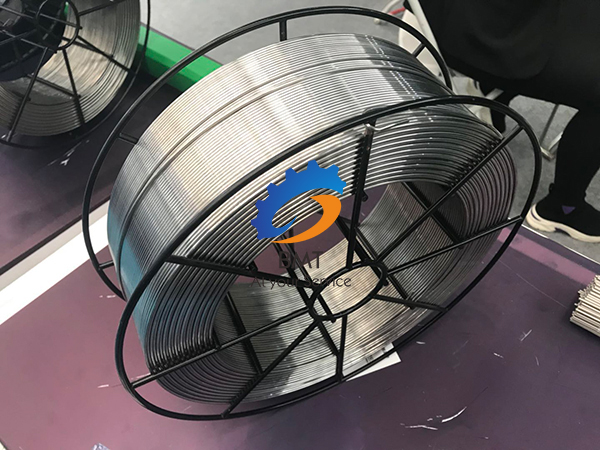

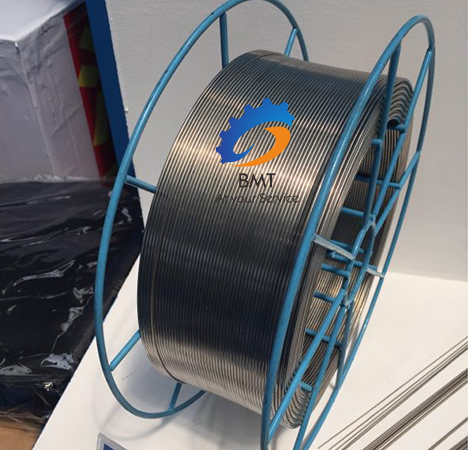

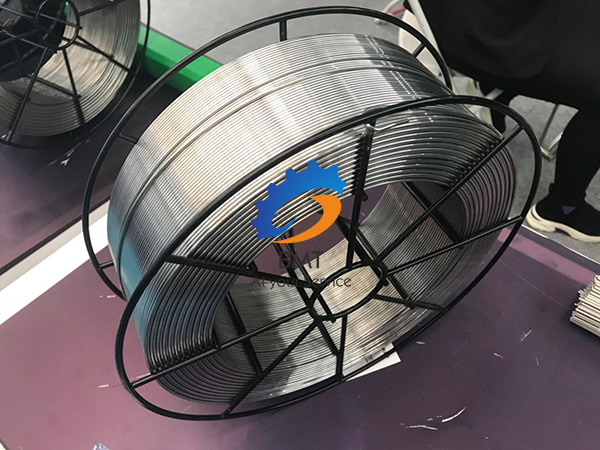

Hoʻokaʻawale ʻia ka uea Titanium i: uea titanium, uea titanium alloy, titanium maʻemaʻe eyeglass uea, titanium pololei uea, titanium uea maʻemaʻe, titanium welding uea, titanium kau uea, titanium disk uea, titanium mālamalama uea, lāʻau titanium uea, titanium nickel alloy uea. .

Nā kikoʻī uea Titanium

A. Nā kikoʻī uea Titanium: φ0.8-φ6.0mm

B. Nā aniani uea titanium kikoʻī: φ1.0-φ6.0mm uea titanium kūikawā

C? Nā kikoʻī uea Titanium: φ0.2-φ8.0mm me ke kau ʻana kūikawā

Kūlana:GB/T,GJB,AWS,ASTM,AMS,JIS

Papa o ke Uea Titanium

GR1, GR2, GR3, GR5, GR7, GR9, GR11, GR12, GR16, etc.

Nā Māhele Noi o ka Uea Titanium

ʻO ka ʻoihana koa, ka lāʻau lapaʻau, nā waiwai haʻuki, nā aniani, nā apo pepeiao, ke poʻo, ke kau ʻana i ka electroplating, ka wili wili a me nā ʻoihana ʻē aʻe.

Mokuaina o ka Uea Titanium

Mokuʻāina hoʻohuihui (M)

Kūlana hana wela (R)

Kūlana hana anu (Y)

(Annealing, Ultra-Generation Testing)

Ili o ke Uea Titanium

ʻili ʻili a i ʻole ka ʻili hoʻomālamalama

Hoʻokumu ka uea Titanium i ka carbide paʻa me ka ʻoi aku ka paʻakikī me ke kalapona. Hoʻoholo ʻia ka ulu ʻana o ka papa kalapona ma waena o ka titanium a me ke kalapona e ka diffusion rate o ka titanium i ka papa carbonized.

He liʻiliʻi ka solubility o ke kalapona i ka titanium, ʻoi aku ka nui o 0.3% ma 850X: a e emi ana ma kahi o 0.1% ma 600C B Ma muli o ka haʻahaʻa haʻahaʻa o ke kalapona i ka titanium, ʻike ʻia ka paʻakikī o ka ʻili ma o ka papa carbide titanium a me kāna akimbo. papa ma lalo. Pono e lawe ʻia ka Carburizing ma lalo o ke ʻano o ka wehe ʻana o ka oxygen, no ka mea, ʻo ka paʻakikī o ka ʻili o ka pauka i hoʻohana mau ʻia no ka carburizing kila e kūʻē i ka ʻili o ka carbon monoxide a i ʻole ka carbon monoxide i loko o ka oxygen a hiki i 2700MPa a me 8500MPa, a me ka mesh. He maʻalahi ke ʻili.

Loaʻa Mea Kimia Hui

Huahana (Max a me Min nui o ke kauoha):palena ʻole, e like me ke kauoha.

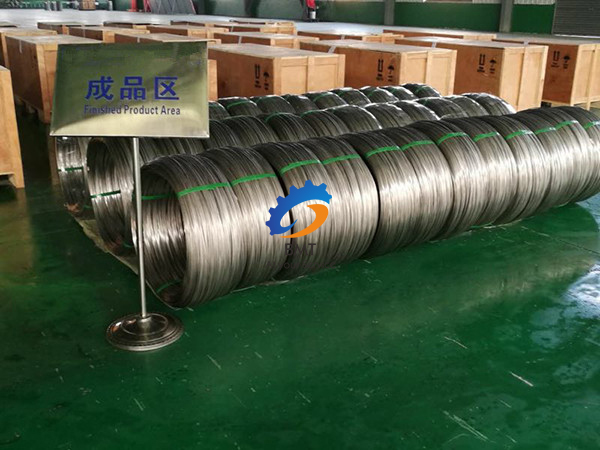

Ka manawa o waena o ka hoʻomaka a i ka wā pau:ʻO ka manawa alakaʻi maʻamau he 30 mau lā. Eia naʻe, pili ia i ka nui o ke kauoha accrdingly.

Kaʻahele:ʻO ke ala maʻamau o ka lawe ʻana ma ke Kai, ma ka Air, ma Express, ma Train, e koho ʻia e nā mea kūʻai.

Hoʻopili:

- E pale ʻia nā ʻaoʻao o ka paipu me ka plastic a i ʻole ka pahu pahu.

- Hoʻopili ʻia nā mea pono a pau e pale i nā welau a me ke alo.

- Hoʻopili ʻia nā waiwai ʻē aʻe a pau e nā pad foam a me nā pahu plastik pili a me nā pahu plywood.

- Pono pono kēlā me kēia lāʻau i hoʻohana ʻia no ka hoʻopili ʻana i mea e pale ai i ka hoʻohaumia ʻana ma o ka hoʻopili ʻana me nā lako hana.

.jpg)

I ka hoʻokaʻawale ʻana, ma lalo o ke ʻano o ka deoxygenation a i ʻole decarburization, hiki ke hoʻokumu ʻia kahi ʻāpana lahilahi o ka titanium carbide i ka wā e carburized i ka lanahu. ʻO ka paʻakikī o kēia papa he 32OUOMPa, kahi e like me ka paʻakikī o ka titanium carbide. ʻOi aku ka hohonu o ka papa carburizing ma mua o ka papa nitriding ke hoʻohana ʻia ka nitriding ma lalo o nā kūlana like. Ma lalo o ke kūlana o ka hoʻonui ʻana i ka oxygen, pono e noʻonoʻo ʻia ka hopena o ka lawe ʻana o ka oxygen i ka hohonu paʻakikī. Aia wale nō ma lalo o ke kūlana o ka mānoanoa o ka ʻili lahilahi e hiki ai ke hoʻokumu ʻia ka ikaika adhesive ma o ka carburizing carbon pauka i loko o ka vacuum a i ʻole i ka lewa argon-methane. ʻO ka ʻokoʻa, ʻo ka hoʻohana ʻana i ka mea hana carburizing kinoea hiki ke hana i kahi papa paʻa paʻa paʻa paʻa paʻa paʻa. I ka manawa like, ua hoʻokumu ʻia ka palahalaha paʻakikī ma ka mahana ma waena o 950T: a me 10201:. Me ka hoʻonui ʻana o ka mānoanoa o ka papa, lilo ka ʻāpana TiC i mea palupalu a ʻāwili. I mea e pale aku ai i ka komo ʻana o nā kalapona i loko o ka papa TiC ma muli o ka decomposition o Reane, pono e hoʻokō ʻia ka carburizing kinoea i loko o kahi kinoea inert me kahi mea hoʻohui i kuhikuhi ʻia ma kahi o 2% Reane. Loaʻa ka paʻakikī o ka ʻili haʻahaʻa i ka wā e kālai ʻia ai ka methane me nā mea hoʻohui propane. Ke piʻi ka ikaika hoʻopaʻa iā OKPA a hoʻohana ʻia ka propane carburized kinoea, ʻoiai ʻoi loa ka lahilahi o ka mānoanoa paʻakikī i ana ʻia, ʻoi aku ka maikaʻi o ka pale ʻana i ka lole. Hoʻopili ʻia ka hydrogen e ka mea hana carburizing kinoea, akā pono e hoʻoneʻe hou ʻia i ka wā annealing.